What are the types of chains? How to choose the suitable chain?

sourceYQ-chinatransmissions

publisherLydia

time2020/08/03

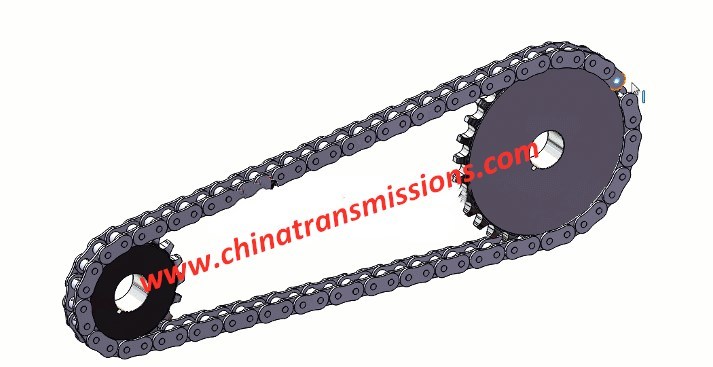

- The chains include short pitch roller chains, double pitch roller chains for transmission, bushing chains for transmission, curved plate roller chains for heavy-duty transmission, toothed chains for transmission, continuously variable transmission chains, and long pitch conveyor chains. , Short pitch roller conveyor chain, double pitch roller conveyor chain, double-speed conveyor chain, plate chain, etc.

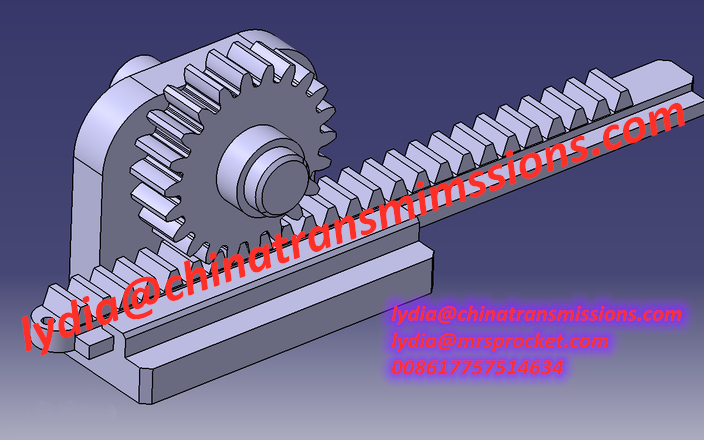

YQ Chinatransmissions-there are many types of sprockets and chains currently on the market.

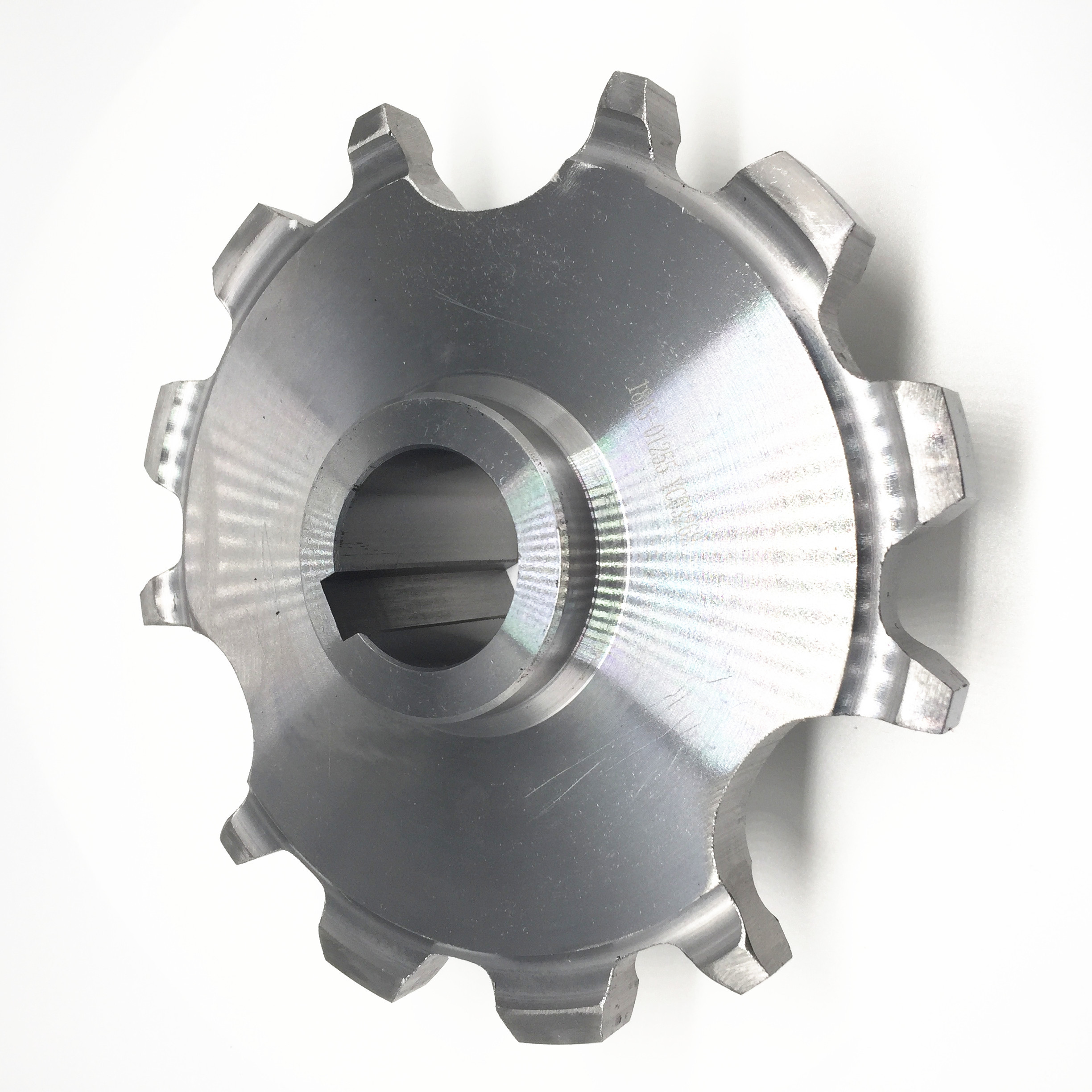

YQ Chains include short-pitch roller chains, double-pitch roller chains for transmission, bushing chains for transmission, curved plate roller chains for heavy-duty transmission, toothed chains for transmission, continuously variable transmission chains, and long-pitch conveyor chains , Short pitch roller conveyor chain, double pitch roller conveyor chain, double-speed conveyor chain, plate chain, etc. Sprockets include multiple-row sprocket, single-row sprocket, stainless steel sprocket, multi-tooth sprocket, hetero-tooth sprocket, etc. There are many types of sprockets and chains, we will not introduce them one by one. We mainly introduce stainless steel chains, nickel-plated chains, galvanized chains, chrome-plated chains, self-lubricating chains, O-ring seal chains, and rubber chains. Kind of chain.

Stainless steel chain: Stainless steel chain is very common in our lives, mainly used in bicycles, motorcycles, automobiles and some load-carrying equipment. This kind of chain is mainly suitable for corrosion-resistant and rust-prone occasions. It can also be used In low temperature and other occasions.

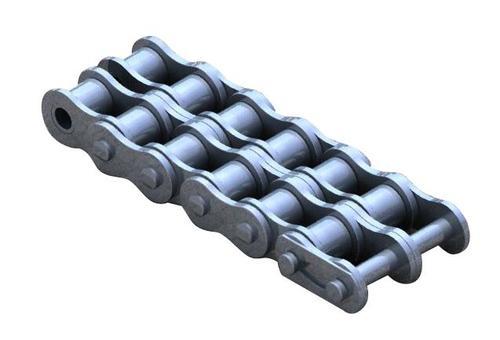

Nickel-plated chain, zinc-plated chain, chrome-plated chain: these are chains composed of carbon steel materials, all of which can be surface treated, and are more suitable for use in rainy or chemically polluted environments, and can also be used in some acid and alkali situations , Its advantage is that it is not easily polluted by chemical products.

Self-lubricating chain: This kind of chain is made of a kind of sintered metal impregnated with lubricating oil. The chain has strong wear resistance and corrosion resistance, and does not require long-term maintenance. It is often cited for high wear resistance and long-term use Among the equipment, such as food automation production line,bicycle racing, low maintenance high precision transmission machinery.

O-ring chain: O-rings for sealing are installed between the inner and outer chain plates of the roller chain to prevent dust from entering and grease from flowing out of the hinge. The stainless steel chain is strictly pre-lubricated. Because the chain has super strong parts and reliable lubrication, it can be used in open transmission such as motorcycles.

Rubber chain: a special kind of chain, which is not often used, but it is used in the production of some precision instruments. This kind of chain has excellent wear resistance and shock resistance, especially the product noise is very small. Precision chain.

We need to choose different chains and sprockets on different occasions, and make reasonable applications according to specific environments and needs.