Different Types of Couplings and Their Application Examples

publisherJulia

time2020/12/08

- Different Types of Couplings and Their Application Examples

Brief introduction

Though couplings are well known and commonly used components in many rotary motion applications, the sheer variety of couplings can make selection rather daunting. While coupling usage is straight forward, most of the design time is spent in selecting the correct coupling type for an application.

Whether you’re building a new machine, or considering making modifications on an existing machine, check out the applications below and see how some industry professionals have applied couplings into their own builds. Though you may need to make adjustments before implementing these into your own designs, you can ensure these applications have already been tested and therefore function reliably.

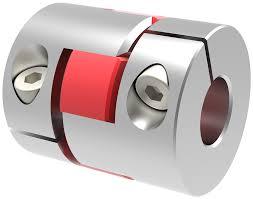

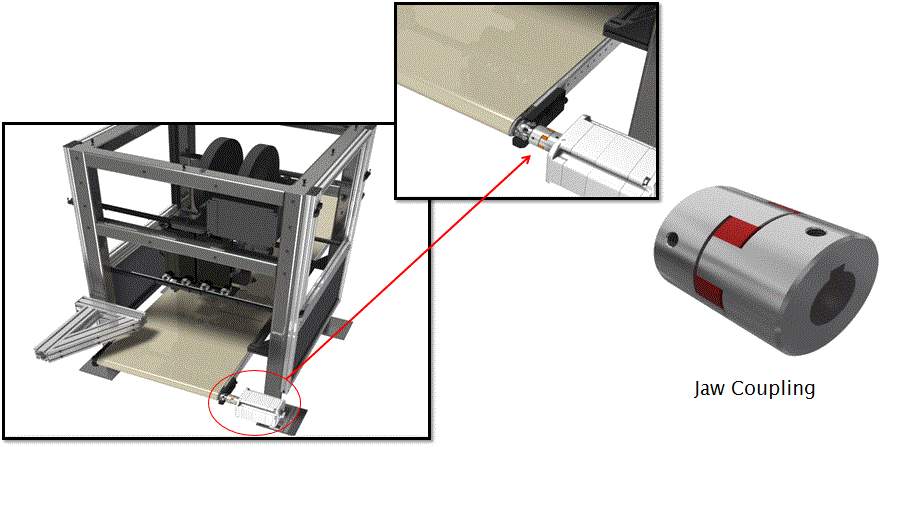

Jaw Coupling Application

The Jaw Coupling is designed to transmit torque while dampening system vibrations and accommodating misalignment. In this particular example we have a coupling used to connect a motor shaft to the drive roller of a conveyor. The Jaw coupling is a good choice for this application since high accuracy and zero back lash are not requirements. At the same time Jaw couplings have good misalignment characteristics and can transmit high torque.

Flexible Coupling Application

Flexible couplings are used to transmit torque from one shaft to another when the two shafts are slightly misaligned. In this example, the test fixture is using torque transducer as torque senor for measuring torque. In this example, the flexible couplings are used to connect the motor and torque sensor with the work piece. These two couplings need to minimize any misalignment error since the torque sensor needs to lay as flat as possible. They also need to protect the sensor from overloading. Major characteristic of the flex couplings are very low or zero backlash, good torsion rigidity as good lateral and angular misalignment capabilities making them very suitable for this application.

Disc Coupling Application

By definition, a disc coupling is a high performance motion control (Servo) coupling designed to be the torque transmitting element (by connecting two shafts together) while accommodating for shaft misalignment. It is designed to be flexible, while remaining torsionally strong under high torque loads. In this example, the coupling is used as part of the slide table in the welding station. The coupling connects the servo motor to ball screws that move the work piece table to the required position or positions. The disc coupling used here was recommended to be used with servo motors due to its low backlash, high torsion rigidity, and good allowable misalignment and torque capabilities.

Couplings are standard machine components that require correct selection based on application requirements and user preference, installation and regular inspection.

During operation, the user should watch for external signs such as abnormal noise and vibration that indicate premature coupling failure. This helps with understanding what caused the failure and how and what to correct prior to installing a new coupling. During their life span, couplings should also be checked for signs of wear and fatigue.

If you have any inquiry, please kindly contact us at any time

Hangzhou YangQi Imp&Exp co.,Ltd

Export Dep of Shengzhou Tomorrow Machinery Co.,Ltd

No.327,North Zhenxing Road, Sanjie Town, Shengzhou City, Zhejiang, China. 312452

Mob/WhatsApp:+8615990115267 Wechat: 0086-13588567269

..........com

julia..........com