9 Types of Gears and Their Applications

publisherHozie

time2020/12/17

- Most machines use gears to perform their movements. Therefore, it is essential to consider which is the most appropriate when making the project.

9 Types of Gears and Their Applications

Most machines use gears to perform their movements. Therefore, it is essential to consider which is the most appropriate when making the project.

When choosing the right gear, the machine will need less energy to perform heavier work, or faster, for example. However, as we see in the title of this article, there are many types of gears and, therefore, it must be very clear the role of each one to optimize the operation of the machine.

Flow Consulting, for example, held a design of a salty-making machine, whose gears were key parts for optimizing their work. In addition to machines, the gears can still be used in equipment, whose energy does not come from an engine.

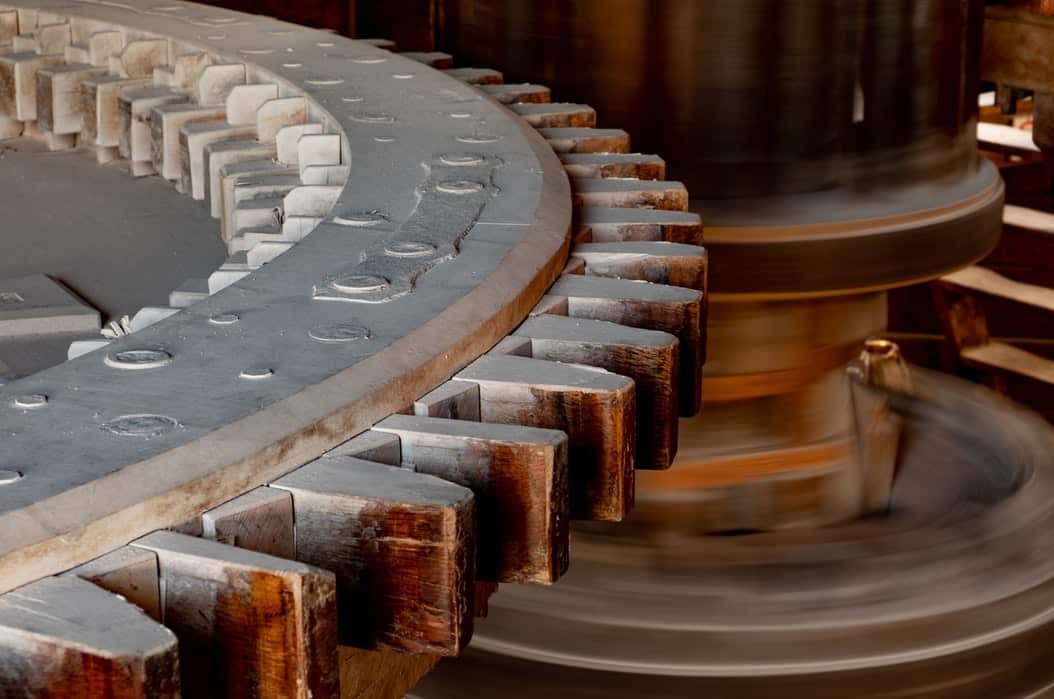

The gears aim to transmit the movement, from one rotating axis to another, which configures a motor rotation through two cylinders. They can touch each other both internally and externally. Or, the rotation can take place between a rotating axis and a rail, which consists of transforming the rotation movement into a translational movement.

Therefore, all gears have the role of transmitting, essentially, the power that is being applied in one gear to the other. Such transmission, in turn, is intended to move another part of the machine, which may decrease or increase the intensity of that same force. This can happen in several ways.

In this article, we will analyze the types of gears available on the market and discuss their applications in diverse sectors, such as aviation and the defense industry.

Types of Gears

Spur Gear

This type of gear has the purpose of making variations in the force and speed of rotation of axles, by changing the size of the gear radius. It has straight teeth, which give the gear its name, and are usually installed on parallel shafts, connecting the teeth of one gear with the other.

This type of gear is easily found on the market and has a low cost compared to others due to its simplicity in production. However, it has the disadvantage of producing noise during operation.

There is still the fact that they are compact, easy to install, and highly reliable.

Another point to consider is that this gear is commonly used to transmit large amounts of energy and is extremely efficient in transmitting the energy supplied to it. It has a small percentage of dissipation and, thus, optimizes the process in which it is inserted.

Spur gears have a wide range of applications, being used in engines, such as marine and automobile, watches, washing machines, steel mills, and in the manufacture of trains. In mechanical watches, for example, they are used to adjust the relative speeds of seconds, minutes, and hours.

Today, these types of gears are also made of I 3D mpressão, which makes their cost cheaper.

Helical Gear

Inclined tooth cylindrical or helical gears are built with teeth that are not aligned and parallel to the axis. Instead, they are angled to define an angle between the axis and the tooth segment.

An advantage of this type of gear is the fact that the entities engage each other little by little, instead of the whole face at the same time . This generates a smaller impact, which is strictly related to the amount of noise produced.

As such, helical tooth cylindrical gears operate more quietly than spur gears , for example.

In addition, we can mention that for a gear of the same width, cylindrical gears with helical teeth can support more load compared to spur gears . This is because the tooth of the first is larger, since it is positioned at an angle. Thus, greater safety is provided when dealing with higher forces and speeds.

Helical tooth cylindrical gears are used in various industry segments, however, being common in the automobile industry, in gearboxes, in the steel industry, in the railway and food industry as well , always having a wide connection with large loads and speeds. It must also be taken into account that, if noise is the main design criterion, it is necessary to choose the helical gear.

Straight Bevel Gear

In this type, the gear has a conical shape. It is important to be more careful with it because it is tilted and, thus, subject to jamming or unhooking. Therefore, the fitting should be done cautiously in order to avoid such problems.

The biggest advantage of the bevel gear is that it can change the direction of a turn and its strength , being able to transmit the energy between axes with different angles between them. Despite this, this is one of the types of gears that require very high precision in assembly.

This is because the shape of the teeth of this type of gear causes the impact of the movement to hit one tooth at a time and, therefore, it can become rough and wear out over time . If care is not taken, there may be greater difficulty in manufacturing, as the geometry of the gear is not easy to make like the cylindrical one.

Another point to be raised is the fact that this is one of the types of gears that do not support high speeds and loads , precisely because the teeth are not parallel to the teeth of the other gear to which it is connected.

The Spur Bevel gear can be of different sizes, as it is used in many machines. Thus, it is up to the person to analyze the correct size of the part for his machine.

Helical Bevel Gear

The helical teeth bevel gear, like the cylindrical gear, has clear differences from the straight. Its shape allows a very large use of the energy that is offered to the gear system. The teeth, being slanted and of greater length, increase efficiency and reduce noise .

It is important to note that, because it is helical, it can withstand high loads and high speeds and, because of that, it must be made of material that supports the impact that one gear will receive from the other, to ensure safety and durability.

As has been said, this is one of the types of gears that are used in machines with systems that can handle higher loads. Transmissions that need, in addition to supporting the load, high transmission speeds, also use this gear.

Hypoid Gear

Hypoids are inserted in the bevel gears, however they have some peculiarities that have advantages over the others. The main one is to have the axes of the gears decentralized , that is, the lines of the axes do not meet. This allows for a translation margin for the second gear shaft, which is compact and can be used in limited spaces.

Another advantage is that hypoids have long teeth, which increases tooth coverage. For this reason, hypoid gears are able to transmit more torque than simple helical gears in the same space.

However, the separation of the shafts causes additional sliding of the teeth and generates a greater amount of heat, forcing the use of special lubricating oils , which are of high viscosity and must be applied periodically. We can see, then, that it is one of the types of gears that requires particular care.

Spiral Gear

Spiral tooth bevel gears feature slanted, curved, spiral teeth, as the name says. It carries with it the main properties of the conics, which is a greater support in terms of very high loads , quiet operation and the optimization of power transmission in relation to non-conics, having a greater efficiency .

Therefore, its particularity consists in the ability to operate with greater numbers of revolutions per minute without major problems . This allows this type of gear to be used in activities that have the objective of reaching higher speeds, such as the automobile industry.

In addition, the bevel gear with spiral teeth is highly requested when there is a need to change the rotation of an axis, since the inclined and curved configuration of its teeth allows such an operation.

Its teeth are fixed at a certain angle, which allows the distribution of pressure and smoothness in the interaction of the parts , characteristics that allow adaptation to numerous activities.

Despite this, due to the special configuration of your teeth, this is one of the types of gears that has a high manufacturing cost . There are companies that produce bevel gear with spiral teeth specific to each project.

Its manufacture and development vary according to the purpose, but it has wide application in the food industry, in its machines and apparatus, in some parts of car engines , along with helical and hypoid gears, in the oil industry and in mining as well.

Worm Gear

The worm gear operates differently from the others.

The mechanism consists of another gear, such as a spur, turning, making the worm gear move too, but at a much lower speed.

Therefore, worm gear is widely used when it is necessary for the speed of transmission of force to a second gear to be reduced.

This type of gear usually has 1:20 reductions, reaching values greater than 1: 300. Most gear models in this case operate at high speeds, and the worm gear is used to decrease this speed , since it has a lower transmission rate.

Another fact is that many worm gears have an interesting property different from the others: the shaft (worm thread), turns the gear (can be spur) easily, but the gear cannot rotate the shaft .

This feature is useful for machines such as conveyors, where the locking function can act as a brake for the conveyor when the engine is not running.

Planetary Gear

The planetary gear is normally made up of 4 gears. They are the solar gear, which is on the outside, the 3 satellite gears, which are those that revolve around the solar and the ring gear, coupled to the support axis.

This type of gear has the role of capturing the high speed of rotation provided by an engine and transforming it into a large torque , which is transmitted to the satellite gears, achieving the optimization of power .

In addition, the planetary gear has advantages over others, as a more compact and lighter product for the power produced and high resistance, even though it is light.

We also have to say that it is ideal for customers who want to achieve high reduction ratios, since this type of gear manages to have a relevant speed reduction in relation to the others.

These gears have applications in automobiles , where smaller torques are required. But in addition, they are used within industries, for example, in controlling wind turbines and paper feeders and electric motors.

Gear Rack

Racks consist of a simple mechanism, but they have many applications.

The cylindrical (or helical) gear, normally of straight teeth, is coupled to the rail, which is called a rack. The two different geometrical shapes of this type of gear (a cylindrical and a straight one) make it possible to transform the circular movement into longitudinal, by means of the horizontal rail, or vice versa.

This gear is generally used in operations that need an operator's control , since the operator can control them by a system where the gear's activity is activated and deactivated.

We find this type of system in the direction of automobiles, in automatic sliding gates , used in most condominiums today, on railroads , allowing the train to pass over steep terrain and in numerous industrial machines .

We can still find the rack in construction elevators , which facilitates the movement of people and materials in the course of the same. Thus, we can see that this type of gear, despite being simple, has many applications and uses in the market.

In general, it is possible to perceive that the types of gears have innumerable uses, in all types of industry and, therefore, it is of paramount importance. Be aware of this fact in the details of the project , before starting to build your machine, to ensure its maximum use .