What are Couplings? | Types of Couplings and their application

publisherJulia

time2021/04/08

- The article will introduce the roller chain couplings and the ways to identify different couplings.

Couplings – the name itself suggests that it couples something(not lovers). You might have an idea or two about couplings but today here in this article, we will know about them in detail. We will be discussing what are couplings, what are the types of couplings & their applications. So let's begin.

What are Couplings?

In simple terms, couplings are mechanical devices that transmit power or torque from one shaft to another.

Couplings are used when the shafts are in a straight line and are to be connected end to end to transmit power.

Power can be transmitted using various gear arrangements or drives only if the shafts are parallel.

Couplings Application

To transmit power from the driving shaft to the driven shaft.

To connect or couple 2 components which are manufactured separately eg. output motor shaft and generator.

To introduce extra flexibility while transmitting power in case of space restrictions.

To introduce protection against overloads.

To reduce the transmission of shock loads from one shaft to another by using flexible couplings.

Couplings Types

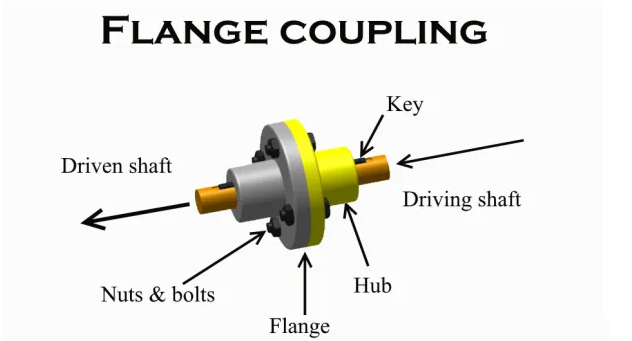

Flange Coupling

Flange coupling is also easy to manufacture and is similar to sleeve coupling. Here, there are flanges on either side of the 2 sleeves. Both flanges consist of an equal number of threaded holes for bolting purposes. The flanges are then joined together with bolts and nuts. A key section is also provided on the hub and shafts so that there is no slipping.

A tapered key is used here. This ensures that the hub doesn't loosen up or move backward and stays attached to the shafts.

Flange couplings are used for medium & heavy-duty industrial applications.

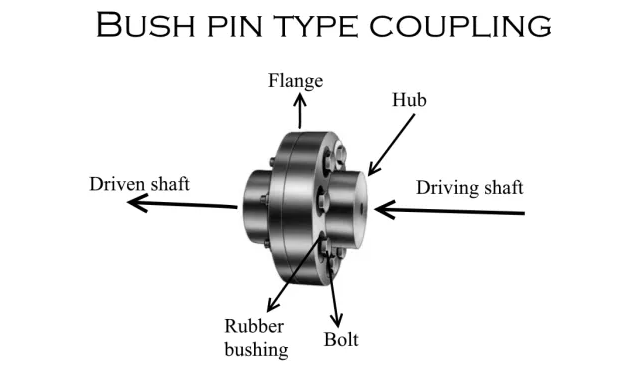

Bush Pin Type Flexible Coupling

You could say that this coupling is an upgraded version of flange coupling. The only difference between them is the usage of rubber bushings. Slightly thick rubber bushings are designed so that the studs or bolts perfectly fit inside it and the bushing fits perfectly inside the holes provided.

The major advantage of using this coupling is that it can be used for slightly misaligned shafts. The rubber bushings add a certain amount of flexibility to the coupling which also helps to absorb shocks and vibrations.

Bush pin-type couplings are used where there is a small amount of angular, parallel, or axial misalignment.

They are used in medium-duty applications in electric motors & machines.

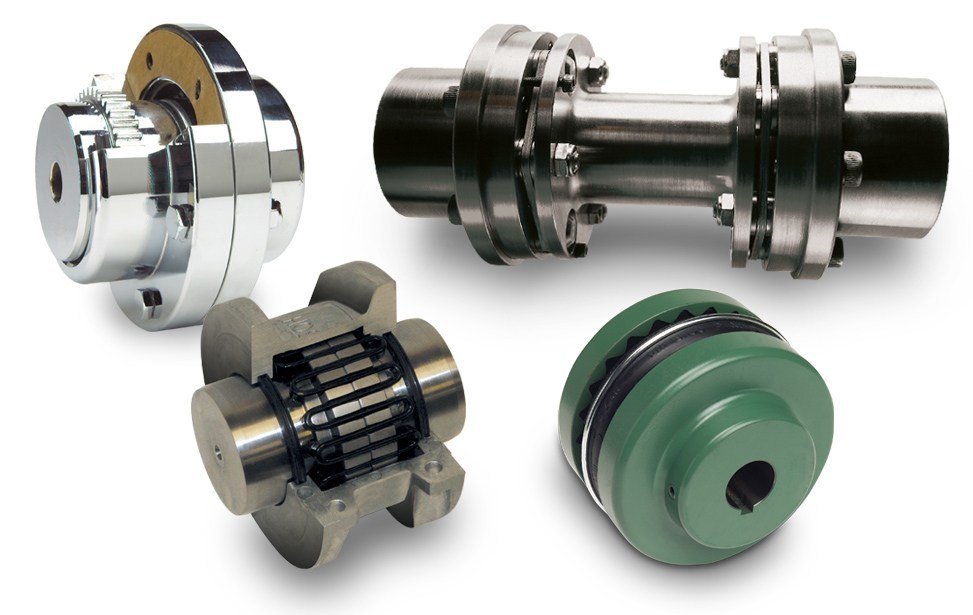

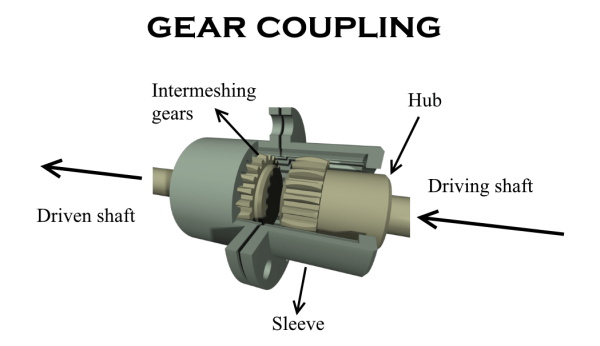

Gear Coupling

The gear coupling is another modified version of the flange coupling. In gear coupling, the flange and hub are different parts assembled instead of a single part as in flange coupling.

The hubs are externally splined but they are so thick and deep that you can regard them as gear teeth. Also, the flanges have internal teeth. The gear ratio is 1:1 and are meshed together. The single-joint gear couplings are limited to lower angular misalignments.

Gear couplings are used for heavy-duty applications where the requirement of torque transmission is higher.

Roller Chain Coupling

Chain couplings consist of identical left and right-hand sprockets that are connected through duplex metal roller chains or acetal plastic chains. Roller chain couplings often incorporate covers similar to those used on other couplings that hold lubricant in place. Acetal plastic chain couplings require no lubrication and thus dispense with covers. Plastic chains transfer less torque than roller chains but are useful in environments where grease is considered a contaminant, where grease can attract dirt and debris, or where atmospheric corrosion is a problem. Chains are connected with pins and master links to create continuous loops. The chain links remain in contact with the sprocket teeth around the entire perimeter of the sprockets. Side clearance between chain and teeth allow for misalignment to exist between the coupled shafts.

CTS | Coupling Manufacturer

CTS®-ChinaTransmissionS is a professional industrial coupling supplier with over 14 years in the power transmission industry.

As a professional coupling supplier, our experienced technical team always learns the latest manufacturing technology.

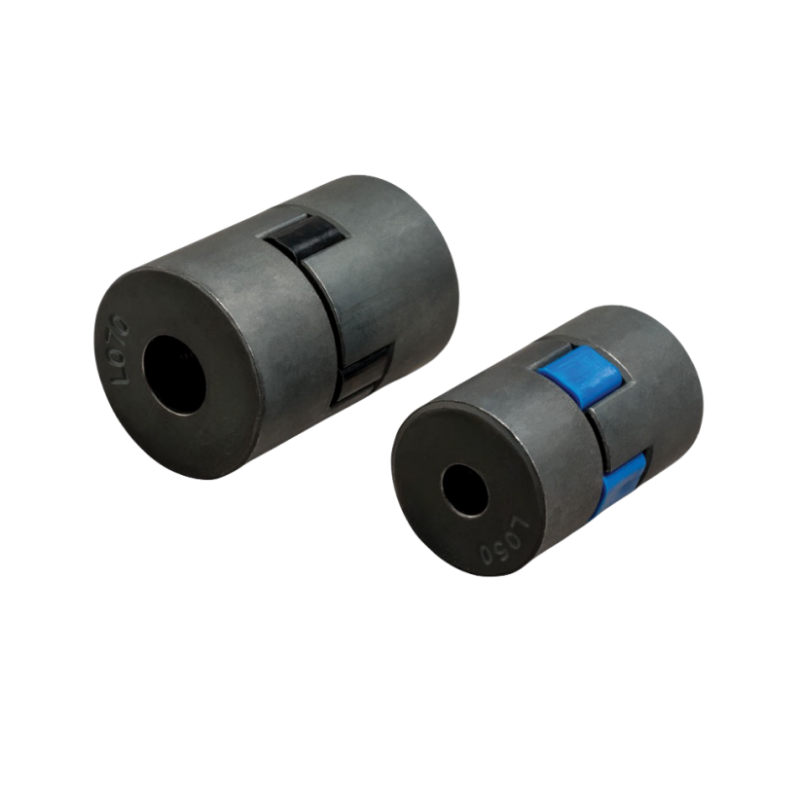

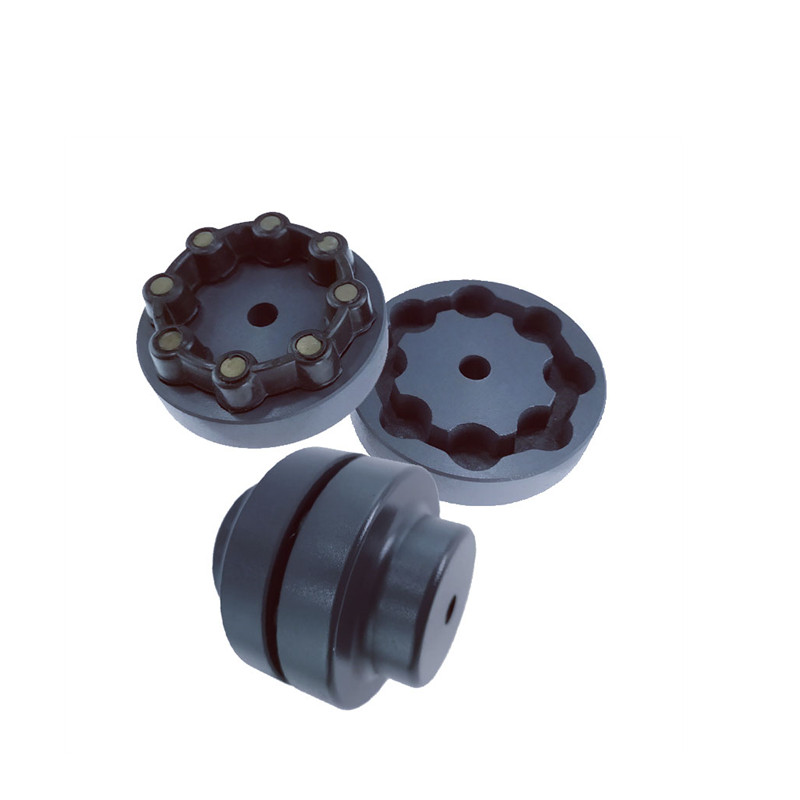

We offer various industrial chain options: Roller Chain Coupling, HRC Coupling, FCL Coupling, L-Jaw Coupling, GE Coupling, MH Coupling, NM Coupling, Tyre Coupling, etc.

If you want to replace your roller chains or have any questions about roller chains, please contact us.