The Process of Hobbing

publisherTaylor

time2021/09/02

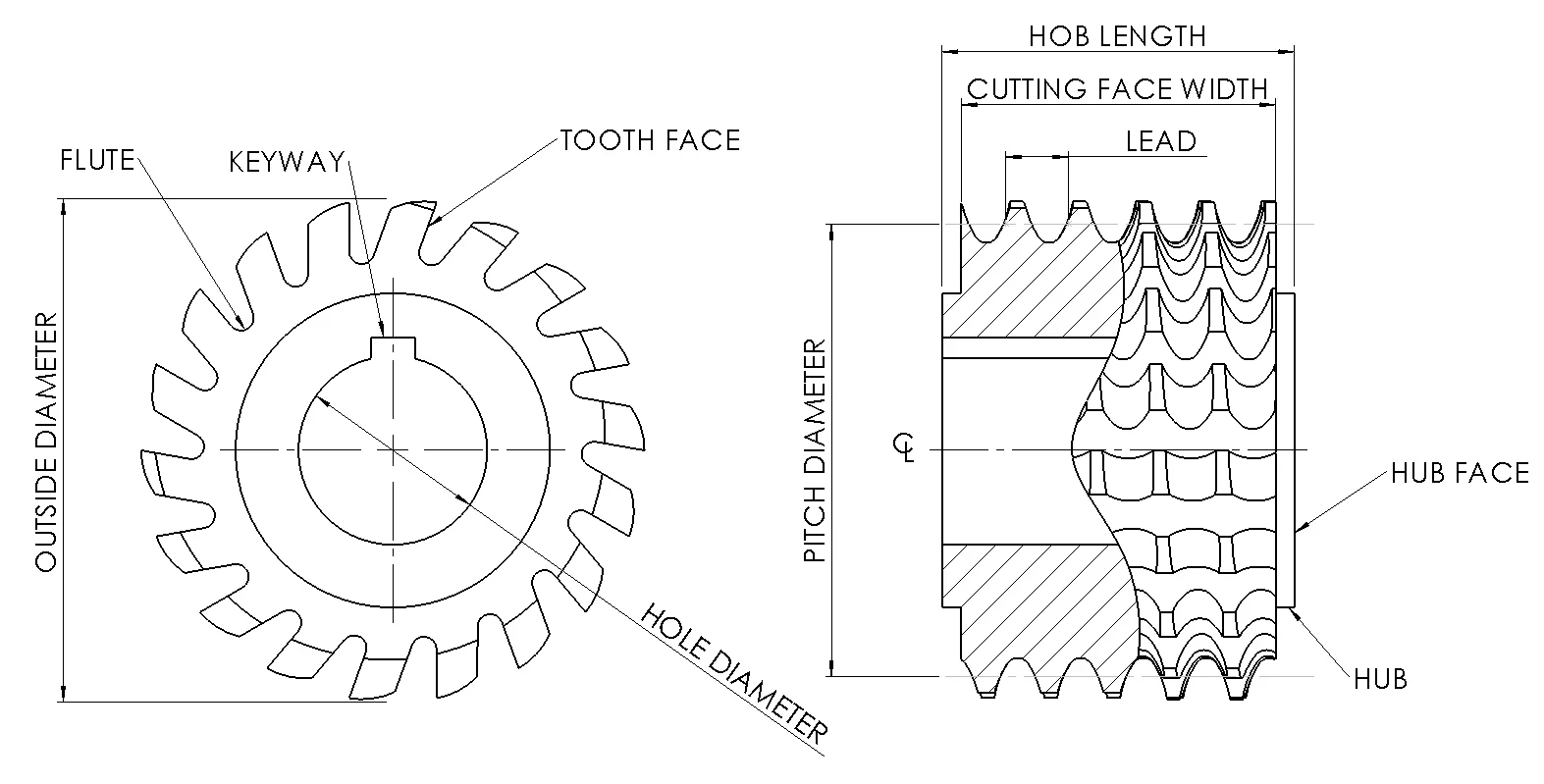

- Hobbing is a machining process for gear cutting, cutting splines, and cutting sprockets on a hobbing machine, which is a special type of milling machine.

What is the Process of Hobbing

Hobbing uses a hobbing machine with two skew spindles, one mounted with a blank workpiece and the other with the hob. The angle between the hob's spindle (axis) and the workpiece's spindle varies, depending on the type of product being produced. For example, if a spur gear is being produced, then the hob is angled equal to the lead angle of the hob; if a helical gear is being produced then the angle must be increased by the same amount as the helix angle of the helical gear. The hobbing features for gears are straight, helical, straight bevel, face, crowned, worm, cylkro and chamfering. The two shafts are rotated at a proportional ratio, which determines the number of teeth on the blank; for example, for a single-threaded hob if the gear ratio is 40:1 the hob rotates 40 times to each turn of the blank, which produces 40 teeth in the blank. If the hob has multiple threads the speed ratio must be multiplied by the number of threads on the hob. The hob is then fed up into the workpiece until the correct tooth depth is obtained. Finally the hob is fed through the workpiece parallel to the blank's axis of rotation. Often, during mass production multiple blanks are stacked using a suitable fixture, then cut in one operation. For very large gears the blank can be gashed to the rough shape first to make hobbing easier.

Contact Us-Welcome To Send Us Inquiries!!!

Taylor Chan

Hangzhou YangQi Imp&Exp Co.,Ltd

杭州阳奇进出口有限公司

Room 1310,Taotiandi Buliding 2,Jianggan District,Hangzhou City ,Zhejiang

sales1..........com

Mob/Whatsapp:+8618857038600

Wechat:lemonchen77

..........com