What is Bevel Gear

publisherTaylor

time2021/09/06

- Bevel gears are gears where the axes of the two shafts intersect and the tooth-bearing faces of the gears themselves are conically shaped. Bevel gears are most often mounted on shafts that are 90 degrees apart, but can be designed to work at other angles as well. The pitch surface of bevel gears is a cone.

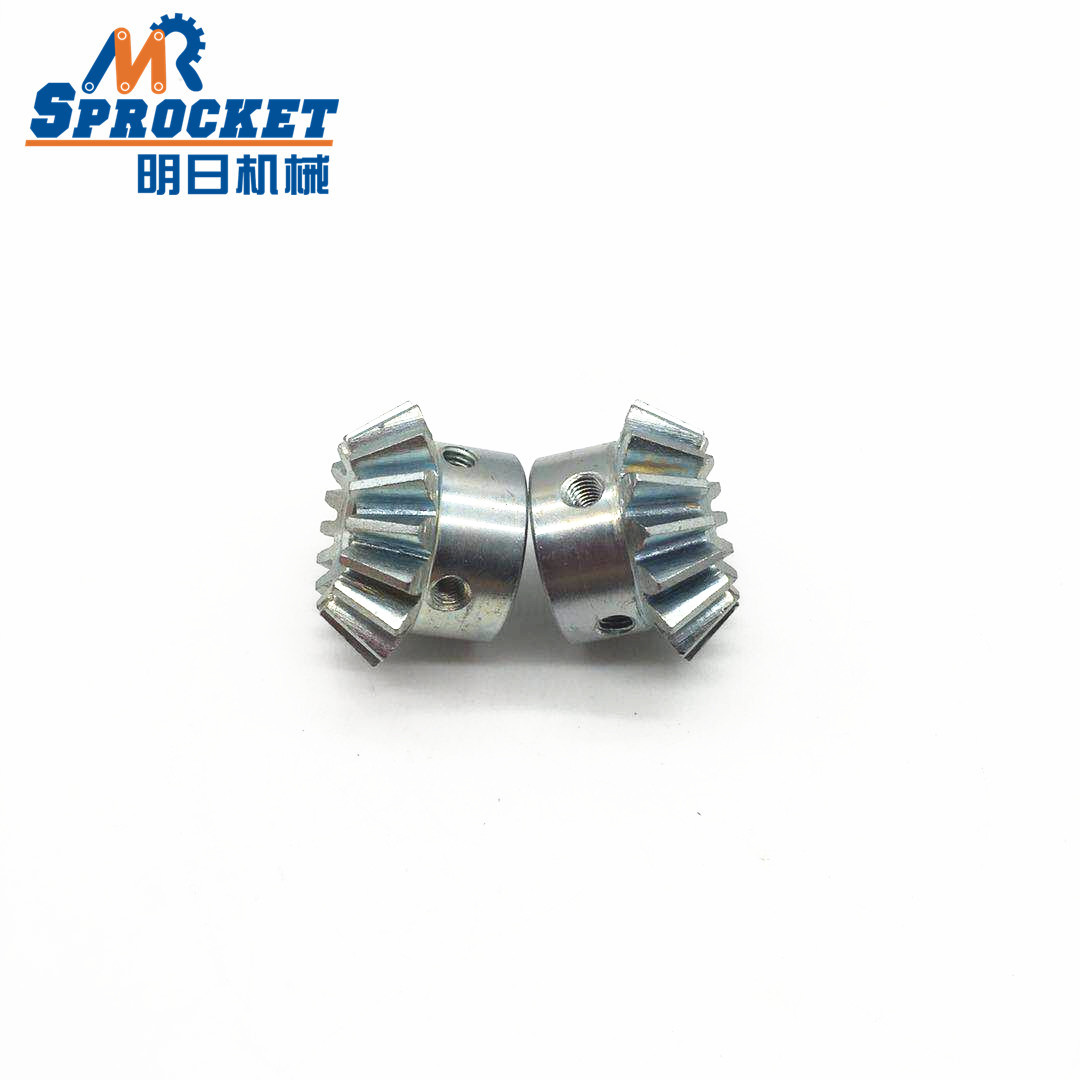

What is Bevel Gear

Bevel gears are gears where the axes of the two shafts intersect and the tooth-bearing faces of the gears themselves are conically shaped. Bevel gears are most often mounted on shafts that are 90 degrees apart, but can be designed to work at other angles as well. The pitch surface of bevel gears is a cone.

Introduction

Two important concepts in gearing are pitch surface and pitch angle. The pitch surface of a gear is the imaginary toothless surface that you would have by averaging out the peaks and valleys of the individual teeth. The pitch surface of an ordinary gear is the shape of a cylinder. The pitch angle of a gear is the angle between the face of the pitch surface and the axis.

The most familiar kinds of bevel gears have pitch angles of less than 90 degrees and therefore are cone-shaped. This type of bevel gear is called external because the gear teeth point outward. The pitch surfaces of meshed external bevel gears are coaxial with the gear shafts; the apexes of the two surfaces are at the point of intersection of the shaft axes.

The use of a genuine bevel gear has even greater importance for the reliability of the axle than any other spare part. Bevel gears that have pitch angles of greater than ninety degrees have teeth that point inward and are called internal bevel gears.

Bevel gears that have pitch angles of exactly 90 degrees have teeth that point outward parallel with the axis and resemble the points on a crown. That's why this type of bevel gear is called a crown gear.

Applications

The bevel gear has many diverse applications such as locomotives, marine applications, automobiles, printing presses, cooling towers, power plants, steel plants, railway track inspection machines, etc.

①Bevel gears are used in differential drives, which can transmit power to two axles spinning at different speeds, such as those on a cornering automobile.

②Bevel gears are used as the main mechanism for a hand drill. As the handle of the drill is turned in a vertical direction, the bevel gears change the rotation of the chuck to a horizontal rotation. The bevel gears in a hand drill have the added advantage of increasing the speed of rotation of the chuck and this makes it possible to drill a range of materials.

③Spiral bevel gears are important components on rotorcraft drive systems. These components are required to operate at high speeds, high loads, and for a large number of load cycles. In this application, spiral bevel gears are used to redirect the shaft from the horizontal gas turbine engine to the vertical rotor. Bevel gears are also used as speed reducers.

Advantages

①This gear makes it possible to change the operating angle.

②Differing of the number of teeth (effectively diameter) on each wheel allows mechanical advantage to be changed. By increasing or decreasing the ratio of teeth between the drive and driven wheels one may change the ratio of rotations between the two, meaning that the rotational drive and torque of the second wheel can be changed in relation to the first, with speed increasing and torque decreasing, or speed decreasing and torque increasing.

Disadvantages

①One wheel of such gear is designed to work with its complementary wheel and no other.

②Must be precisely mounted.

③The shafts' bearings must be capable of supporting significant forces.

Contact Us-Welcome To Send Us Inquiries!!!

Taylor Chan

Hangzhou YangQi Imp&Exp Co.,Ltd

杭州阳奇进出口有限公司

Room 1310,Taotiandi Buliding 2,Jianggan District,Hangzhou City ,Zhejiang

sales1..........com

Mob/Whatsapp:+8618857038600

Wechat:lemonchen77

..........com