The Introduction Of Driver Chain

publisherKimer

time2022/01/11

- In the machine tool transmission, the commonly used transmission parts are pulleys, gears, worm turbines, racks and pinions and screw nuts. Through these transmission parts, the power source and the actuator are connected, or the two actuators are connected, which is called transmission connection.

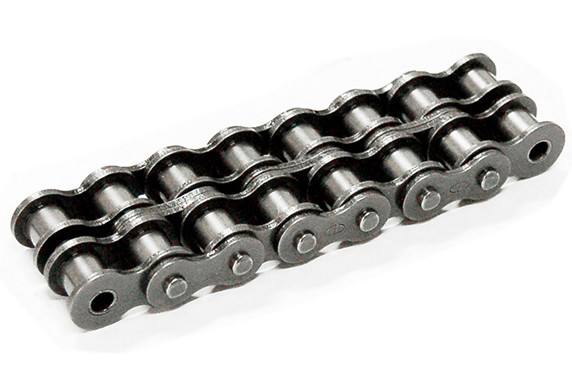

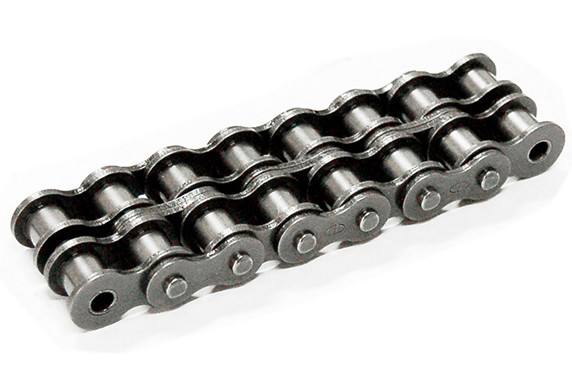

The Introduction Of Driver Chain

In the machine tool transmission, the commonly used transmission parts are pulleys, gears, worm turbines, racks and pinions and screw nuts. Through these transmission parts, the power source and the actuator are connected, or the two actuators are connected, which is called transmission connection. A series of sequentially arranged transmission parts that constitute a transmission connection is called a transmission chain.

The transmission chain usually contains two types of transmission mechanisms: one is a transmission mechanism with a fixed transmission ratio and transmission direction, such as a fixed ratio gear pair, a worm turbine pair, etc., which is called a fixed ratio transmission mechanism; the other is based on processing requirements. A transmission mechanism that can change the transmission ratio and transmission direction, such as a hanging wheel transmission mechanism, a sliding gear transmission mechanism, etc., is called a replacement mechanism.

according to.

The characteristics of transmission chain are as follows: 1. Compared with belt transmission, it has no elastic sliding, can maintain accurate average transmission ratio and has higher transmission efficiency; the chain does not need large tension force, so the load on the shaft and bearing is smaller; it can not slip, drive reliably, and has strong overload capacity, and can work well under low speed and heavy load; 2. It is in transmission phase with gear. It can work in high temperature and dusty environment with lower cost. 3. The disadvantage is that the instantaneous chain speed and the instantaneous transmission ratio are changeable, the transmission stability is poor, there are impact and noise in the work, and it is not suitable for high-speed situation, and it is not suitable for the situation of frequent changes in rotation direction.

Contact Us-Welcome To Send Us Inquiries!!!

Kimer Zheng

Hangzhou YangQi Imp&Exp Co.,Ltd

杭州阳奇进出口有限公司

Room 1310,Taotiandi Buliding 2,Jianggan District,Hangzhou City ,Zhejiang

Sales2..........Com

Mob/Whatsapp/wechat:+8618258831202

..........Com