The introduction of chain coupling

publisherKimer

time2022/07/18

- The chain coupling uses a common chain and meshes with two parallel sprockets with the same number of teeth at the same time. The main difference between the chain couplings of different structural types is the use of different chains. Roller chain coupling, toothed chain coupling, nylon chain coupling, etc.

The Introduction Of Chain Coupling

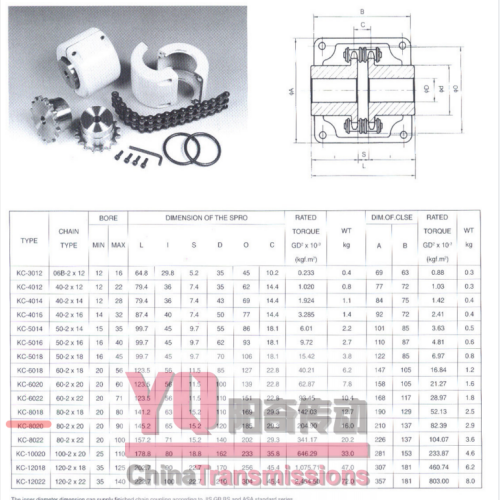

The chain coupling uses a common chain and meshes with two parallel sprockets with the same number of teeth at the same time. The main difference between the chain couplings of different structural types is the use of different chains. Roller chain coupling, toothed chain coupling, nylon chain coupling, etc. The chain coupling has the advantages of simple structure (composed of four parts), convenient assembly and disassembly, no need to move the connected two shafts during disassembly, compact size, light weight, certain compensation ability, low installation accuracy, reliable operation and long life. Longer and lower cost. It can be used for shafting transmission of textile, agricultural machinery, hoisting and transportation, engineering, mining, light industry, chemical industry and other machinery. It is suitable for high temperature, humid and dusty environment, not suitable for high speed, severe impact load and transmission of axial force. The chain coupling should work under the condition of good lubrication and protective cover.

The Components Of Chain Coupling :Aluminum shell +two sprockets +double chain

KC6022: 60 means the type of sprockets and chains 22 means the teeth of sprocket

Contact Us-Welcome To Send Us Inquiries!!!

Kimer Zheng

Hangzhou YangQi Imp&Exp Co.,Ltd

杭州阳奇进出口有限公司

Room 1310,Taotiandi Buliding 2,Jianggan District,Hangzhou City ,Zhejiang

Sales2..........Com

Mob/Whatsapp/wechat:+008618258831202

..........Com