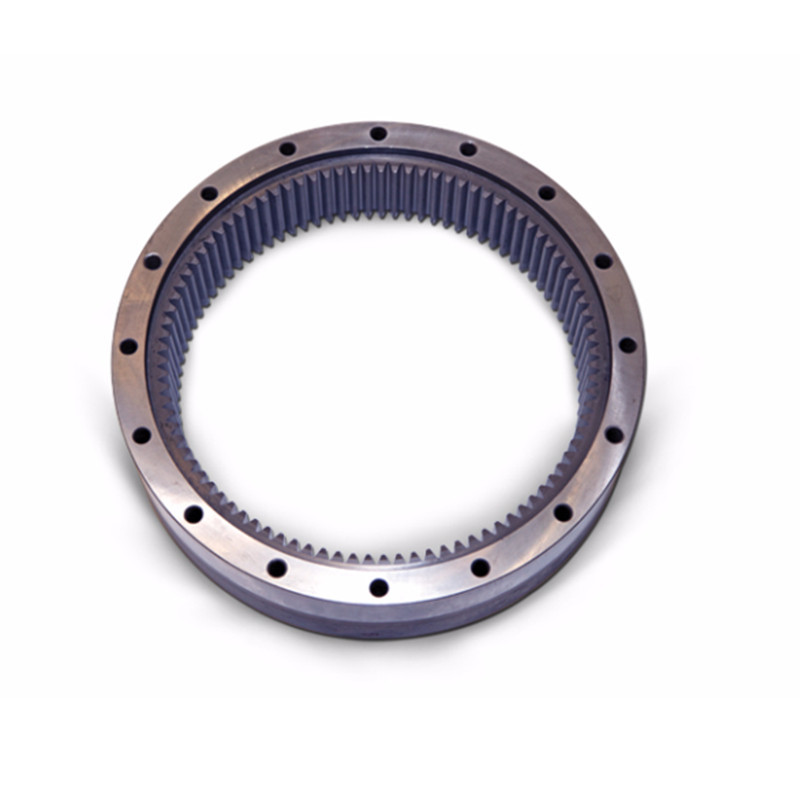

How To Hobbing Inner Gear?

publisherKimer

time2023/09/05

- Hobbing the inner gear is a common gear manufacturing process. The general steps for hobbing the inner gear include machine setup, workpiece preparation, hobbing cutter selection, tool setup, determination of cutting parameters, cutting operation, cooling and lubrication, quality control, and finishing steps. It requires specialized equipment and expertise, and the specific steps and techniques may vary depending on the machine and gear design requirements.

How To Hobbing The Inner Gear

Hobbing is a commonly used manufacturing process for cutting gears, including inner gears. Here are the general steps to hob the inner gear

Machine Setup:

Set up the hobbing machine, ensuring that it is properly calibrated and aligned for the gear cutting operation. The machine should be equipped with a hobbing cutter suitable for cutting internal gears.

Workpiece Preparation:

Secure the workpiece, which is the gear blank, onto the hobbing machine's spindle. Make sure it is firmly held in place to prevent movement during the cutting process.

Hobbing Cutter Selection:

Choose the appropriate hobbing cutter for cutting the inner gear. The cutter should have teeth designed to match the desired gear tooth profile. Consider factors such as the gear size, module, pressure angle, and tooth count when selecting the cutter.

Tool Setup:

Mount the hobbing cutter onto the hobbing machine, ensuring it is centered and aligned properly. Set the cutter's position and distance relative to the workpiece according to the industry gear's specifications.

Cutting Parameters:

Determine the cutting parameters such as hob rotation speed, feed rate, and axial depth of cut. These parameters will depend on the material being cut and the desired tooth profile. Consult the machine's manual, gear manufacturing standards, or expert knowledge to determine suitable cutting parameters

Cooling and Lubrication:

Apply an appropriate cutting fluid or lubricant to the cutting area to reduce heat and friction, prolong tool life, and improve surface finish.

It's important to note that hobbing gears, especially internal gears, requires specialized equipment and expertise. The specific process and techniques may vary depending on the machine used and the gear's design requirements.

Contact Us-Welcome To Send Us Inquiries!!!

Kimer Zheng

Hangzhou YangQi Imp&Exp Co.,Ltd

杭州阳奇进出口有限公司

Room 1310,Taotiandi Buliding 2,Jianggan District,Hangzhou City ,Zhejiang

Mob/Whatsapp/wechat:+008618258831202

..........Com