what are taper bore sprockets and its advantage

publisherRobert

time2023/09/11

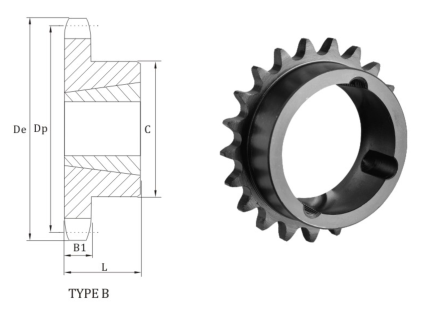

- Taper bore sprockets are a type of sprocket used in various mechanical systems, especially in power transmission applications like conveyor systems, industrial machinery, and roller chains. These sprockets are designed with a tapered bore, which means the central hole (bore) through which they are mounted onto a shaft is tapered or conical in shape.

What are Taper Bore Sprockets and Its Advantage

Introduction to tapered hole sprockets

Taper bore sprockets are special sprockets used in mechanical systems for efficient power transmission. They have a central hole with a tapered or conical shape, making them easy to install on tapered shafts without the need for additional fasteners like set screws or keyways. This design ensures a secure connection between the sprocket and the shaft, reducing the risk of slippage during operation. Taper bore sprockets are versatile, accommodating a range of shaft sizes, and they are commonly used in industrial machinery and conveyor systems for reliable power transmission.

Taper bore sprockets are commonly made from materials such as steel or cast iron and are available in various tooth counts and sizes to match the requirements of different chain drives or belt drives. They are an important component in many industrial and mechanical systems, ensuring reliable power transmission.

The tapered bore design offers several advantage

1. Easy Installation: Taper bore sprockets are designed to be mounted on a tapered shaft. When the sprocket is slid onto the shaft, it self-centers and locks securely in place due to the taper, eliminating the need for additional locking devices such as set screws or keyways. This simplifies installation and reduces the risk of sprocket slippage.

2. Secure Shaft Connection: The taper bore design provides a tight and secure fit between the sprocket and the shaft, ensuring efficient power transmission and minimizing the risk of sprocket wobbling or coming loose during operation.

3. Versatility: Taper bore sprockets can accommodate a range of shaft sizes with the same sprocket, as long as the shaft diameter falls within the specified taper bore range. This versatility can reduce the need for stocking multiple sprocket sizes.

4. Maintenance: When maintenance or replacement is necessary, taper bore sprockets can be easily removed from the shaft using appropriate tools and can be reused on different shafts without compromising their integrity.

Contact Us

Robert Tsui

Hangzhou YangQi Imp&Exp co.,Ltd

Email: sales4..........com

Mob: 0086-19357396509 Wechat: AAALong0215 QQ:1961229394