Roller Chain Care and Maintenance

publisherRobert

time2023/09/11

- Dirt and contaminants can cause premature wear and affect the performance of the roller chain. Regularly remove any accumulated dirt or debris from the roller chain using a brush or compressed air.

Roller Chain Care and Maintenance

The Importance of Roller Chain Maintenance

Reducing Failures and Downtime: Regular maintenance of roller chains allows for the detection and correction of potential issues, reducing the risk of mechanical failures and minimizing unnecessary downtime and production interruptions.

Extending Lifespan: Proper maintenance and care can reduce wear and damage to roller chains, thus extending their lifespan and reducing the frequency and cost of chain replacements.

Improving Efficiency: Regular lubrication, cleaning, and adjustment of roller chains help keep them running smoothly, enhancing the efficiency of mechanical systems

Ensuring Safety: Damaged oand reducing energy consumption.

r severely worn roller chains can lead to hazardous situations, such as chain breakage or disengagement, which can jeopardize the safety of operators. Maintenance of roller chains helps mitigate these potential safety risks.

Cost Savings: Regular maintenance and care of roller chains typically cost less than replacing damaged chains. Furthermore, by prolonging the lifespan of roller chains and improving the efficiency of mechanical systems, operational costs can be reduced.

Maintaining Quality: In applications that require high precision and reliability, such as production lines and automation systems, roller chain maintenance is essential to ensuring product quality and consistency.

Some Common Steps and Considerations for Maintaining Roller Chains

Regular Lubrication: Lubricate the roller chain with the appropriate type and amount of lubricant. Lubrication helps reduce friction and wear in the chain, ensuring smooth operation between chain links and sprockets. Follow the manufacturer's recommendations or the operator's manual to ensure lubrication at the appropriate intervals.

Keep it Clean: Regularly clean the roller chain, especially in environments where dust, dirt, or other impurities are likely to accumulate. Use suitable cleaning tools and solvents to keep the chain and sprocket surfaces clean, reducing wear.

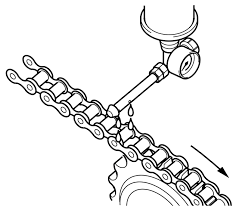

Check Chain Tension: Maintain the proper chain tension. Loose chains can lead to chain derailing or faster wear. Regularly check chain tension and make necessary adjustments, following the manufacturer's recommendations.

Inspect for Wear: Periodically inspect the roller chain and sprockets for signs of wear. If significant wear or damage is found, replace the damaged components promptly to prevent further harm.

Avoid Overloading: Ensure that you do not exceed the roller chain's rated working load. Overloading can lead to chain and sprocket damage, shortening their lifespan.

Prevent Corrosion: If the working environment is likely to cause corrosion, use appropriate lubricants or corrosion inhibitors to protect the chain's surface.

Maintain Records: Keeping maintenance records is essential. Document the dates and details of activities such as lubrication, tension adjustments, and component replacements for regular maintenance planning.

Follow Manufacturer's Recommendations: Follow the manufacturer's maintenance guidelines and recommendations. Different types of roller chains may have varying maintenance requirements.

Contact Us

Robert Tsui

Hangzhou YangQi Imp&Exp co.,Ltd

Email: sales4..........com

Mob: 0086-19357396509 Wechat: AAALong0215 QQ:1961229394