What is Tooth Harding

publisherRobert

time2023/09/11

- "Tooth harding" is a heat treatment process commonly used to enhance the hardness and wear resistance of gears and toothed components. In this process, gears or toothed components are first heated to a specific temperature, typically above the critical point, to alter their crystalline structure. Subsequently, rapid cooling, often using oil, water, or gas, is employed to cool the heat-treated region, thereby harding it.

What is Tooth Harding

The Process of Tooth Harding

The process of tooth harding begins with the careful selection of gears or sprocket that require enhanced surface properties. These components are meticulously heated to a specific temperature range, typically above the transformation point of the material. This controlled heating induces changes in the material's microstructure, such as the formation of martensite, which is a harder and more wear-resistant phase compared to the original structure.

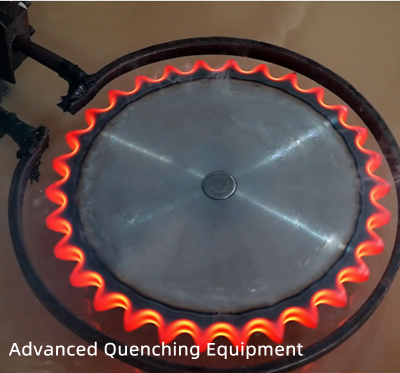

Following the controlled heating phase, a rapid quenching process is employed. This can involve immersion in a quenching medium such as oil, water, or gas, depending on the specific material and requirements of the application. The rapid cooling causes the surface of the gear teeth to harden while maintaining the core's ductility and toughness, ensuring that the gear can withstand the mechanical stresses it will encounter during operation.

The Advantage of Tooth Harding

1.Enhanced Hardness and Wear Resistance: Hardening treatment significantly improves the hardness of sprocket teeth, making them more wear-resistant. This is crucial for high-load and frequently used sprocket applications, extending the sprocket's lifespan.

2. Improved Fatigue Resistance: Tooth hardening not only increases hardness but also enhances the sprocket's fatigue resistance. This means that sprockets can better withstand repeated loading and unloading stresses, reducing the risk of fatigue failure.

3. Reduced Friction and Wear: Hardening treatment reduces friction and wear between sprocket teeth and chains, enhancing transmission efficiency and minimizing energy loss.

4. Enhanced Precision and Reliability: Tooth hardening improves the precision of sprocket teeth, ensuring their dimensions and shapes remain stable and enhancing the reliability of the transmission system.

5. Suitable for High-Load Applications: Sprockets are commonly used in applications that experience high loads, such as industrial machinery and heavy equipment. Tooth hardening enables sprockets to better handle these challenging working conditions.

6. Extended Service Life: Due to the improved durability and wear resistance of sprocket teeth resulting from hardening treatment, the service life of sprockets can be extended, reducing replacement and maintenance costs.

Contact Us

Robert Tsui

Hangzhou YangQi Imp&Exp co.,Ltd

Email: sales4..........com

Mob: 0086-19357396509 Wechat: AAALong0215 QQ:1961229394