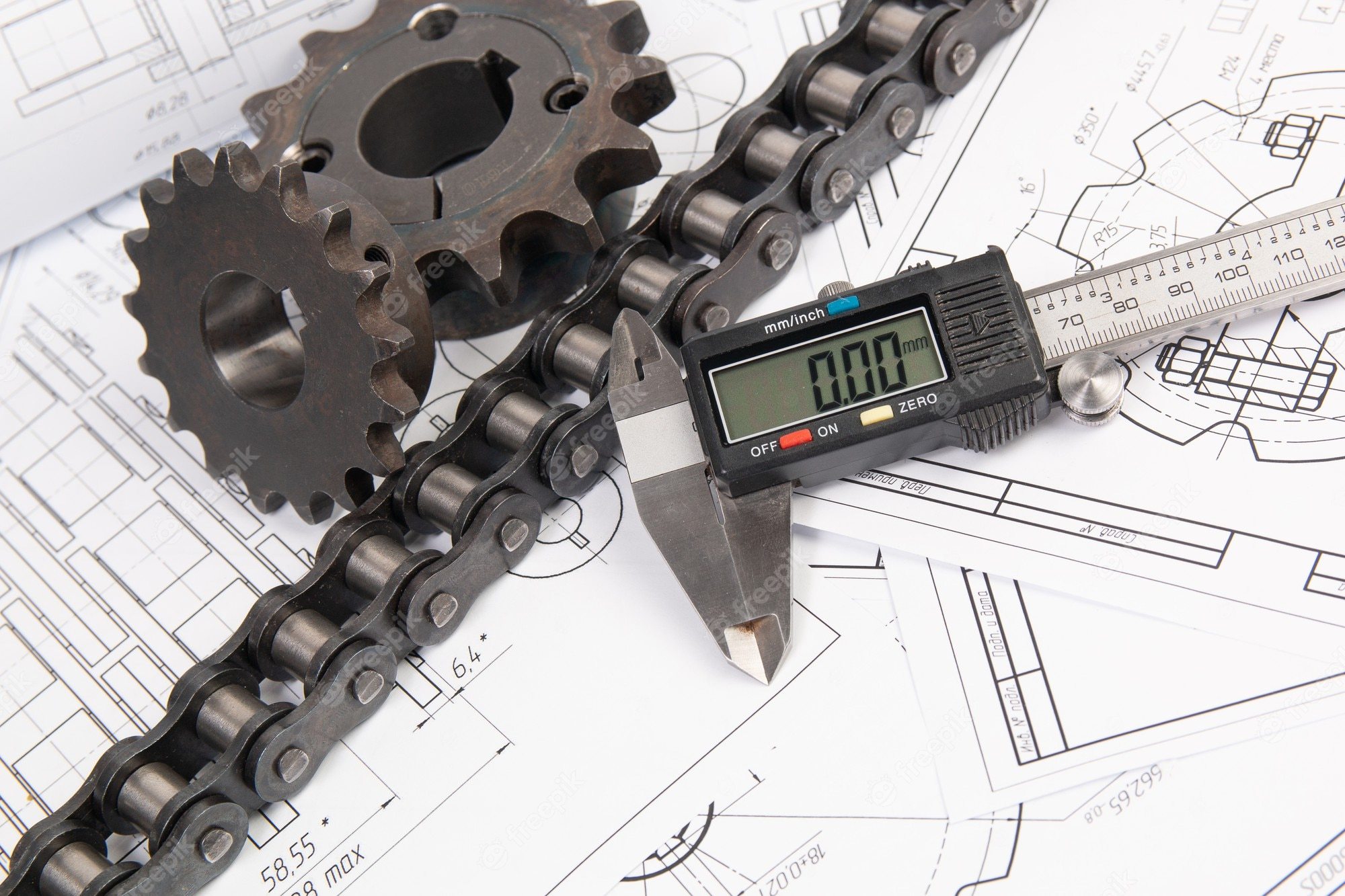

HOW TO REPLACE THE CHAIN, SPROCKETS AND BUSHES

publisherEmma

time2023/09/14

- Replacing the chain, sprockets, and bushes typically involves several steps.

HOW TO REPLACE THE CHAIN, SPROCKETS AND BUSHES

Replacing the chain, sprockets, and bushes typically involves several steps. Here is a general guide to help you through the process:

Steps:

Gather the necessary tools and materials: You will need a new chain, sprockets, and bushes that match the specifications of your equipment. Additionally, you will need appropriate hand tools such as wrenches, sockets, and a chain breaker tool.

Prepare the work area: Find a clean and well-lit workspace where you can safely perform the replacement. It's also a good idea to have a workbench or sturdy surface to hold the equipment.

Remove the old chain: Start by loosening the tension on the existing chain. This typically involves adjusting the tensioner or removing a master link, if present. Then, use a chain breaker tool to disconnect the chain by pushing out one of the pins. Remove the chain from the sprockets.

Remove the old sprockets: Carefully inspect the sprockets and check for any signs of wear or damage. To remove the sprockets, you may need to loosen bolts or nuts securing them in place. Use appropriate tools to remove the sprockets from their respective shafts.

Replace the bushes (if applicable): If your equipment has bushes that are worn or damaged, carefully remove them using suitable tools. Install new bushes that match the specifications and size required by your equipment.

Install the new sprockets: Take the new sprockets and align them with their respective shafts. Use the appropriate fasteners to secure them in place. Ensure that the sprockets are properly aligned and have the correct orientation relative to each other.

Install the new chain: Thread the new chain through the sprockets, ensuring it engages correctly with the teeth. Follow the manufacturer's instructions for proper chain installation, including any specific tensioning procedures.

Adjust the chain tension: Use the appropriate tensioning method specified for your equipment (such as an adjustable tensioner or manual adjustment) to set the correct tension on the chain. Refer to your equipment's manual for guidance on proper chain tensioning.

Check for proper alignment and tension: Rotate the chain and sprockets by hand to ensure smooth operation and proper engagement. Verify that the chain is well-aligned and properly tensioned. Make any necessary adjustments as required.

Test and finalize: Before operating the equipment, test the chain, sprockets, and bushes to ensure they function correctly and that there are no abnormal vibrations or noises. Once everything is in satisfactory condition, secure any fasteners and complete the replacement process.

Contact Us-Welcome To Send Us Inquiries!!!

Emma Chen

Hangzhou YangQi Imp&Exp Co.,Ltd

杭州阳奇进出口有限公司

Room 1310,Taotiandi Buliding 2,Jianggan District,Hangzhou City ,Zhejiang

Mob/Whatsapp/wechat:+008615968657609

..........Com

If you have any other needs, please click:Sprocket、Roller chain、Gear Rack、Pulley、Timing Pulley、Coupling