Customized Spur Gear And Pinion | Unstandard Industrial Spur Gears | Spur Gear Manufacturer | Custom Service

- group name

- Customized Sprockets

- Min Order

- 1 piece

- brand name

- CTS-ChinaTransmissionS

- Nearest port for product export

- Shanghai, Ningbo, Tianjing, Guangzhou

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, PayPal, Westem Union, Cash

- update time

- Sun, 02 Nov 2025 08:29:00 GMT

Paramtents

Material Carbon Steel

Color Natural

Surface Treatment Shot Peening/Heat Treatment/Grinding

Accuracy Precision teeth for optimum performance

Quality Durable Spur Gear

Interchangeability Directly interchangeable with other brands

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

About Customized Spur Gear

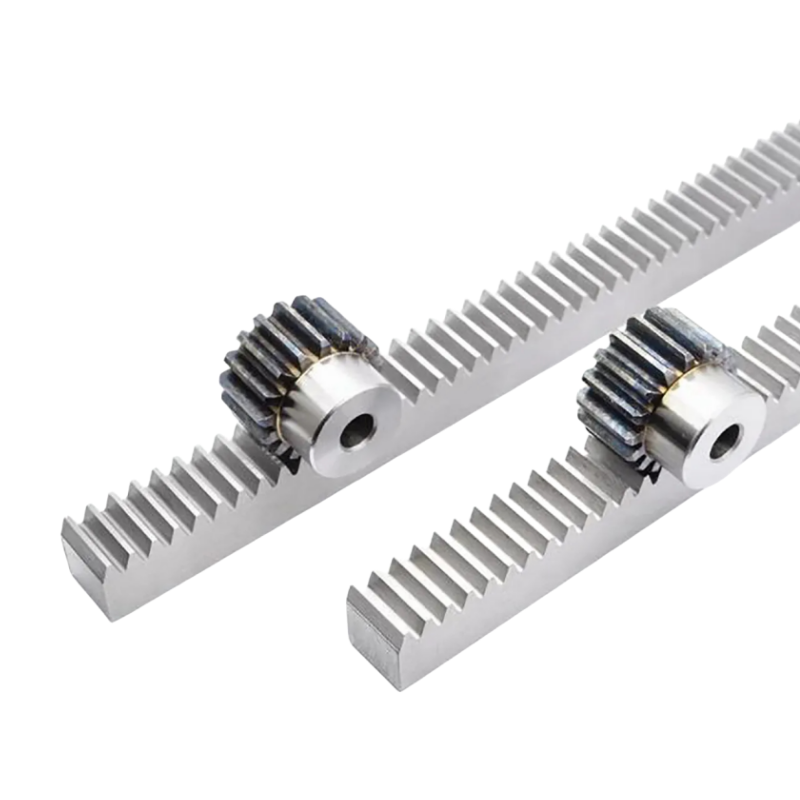

CTS® Custom Spur Gear

The gears are different from the standard spur gears, whose inner bore is not round but has four slots. The slots will strengthen the adhesion when operating with other parts. Most of us think the gears are ice-cold steel parts, but this gear looks like an artwork, equipped with delicate radian.

We can supply precision standard gears and custom gears. According to your needs for different working conditions, it can be used for normalizing, quenching and tempering, carburizing, and quenching. Our factory has high-precision grinders, CNC forming grinders, surface grinders, cylindrical grinders, gear hobbing machines, and other finishing equipment, which can grind straight gears, helical gears, spiral bevel gears, gear shafts, and other gear products. At the same time, various non-standard special transmission machinery products can be produced according to user requirements.

Quality Assurance:

ISO9001: 2015 and GB/T24001-2016 / ISO14001: 2015.

Features

- OEM Gears

- High-precision Gears

- Directly interchangeable with other brands

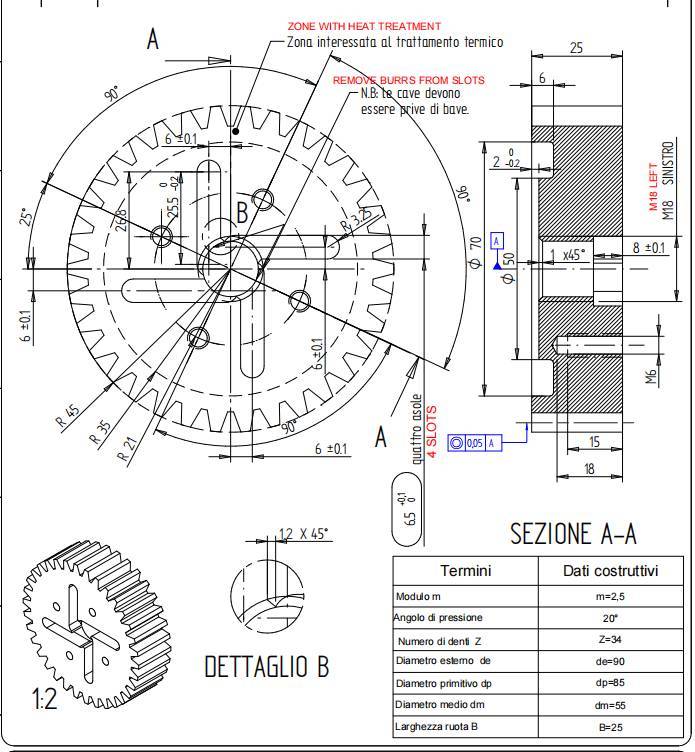

Customized Spur Gear Dimension and Drawing

|

Types

|

External diameter(de)

|

Pitch Diameter (dp)

|

Number of Teeth

|

Hub diameter (dm) | Tooth width "A" (mm) |

M2.5 Z=34 | 90 | 85 | 34 | No hub | 18 |

How To Custom Spur Gear

Custom Gear Types:

| Spur Gears | Ideal for straightforward, high-efficiency motion |

| Helical Gears | Offer smoother and quieter operation, suitable for high-speed applications. |

| Worm Gears | Used for precise motion control and right-angle configurations. |