ANSI #80B Plain Bore Stainless Steel Sprockets

- group name

- ANSI 80 Sprockets

- Min Order

- 1 piece

- brand name

- CTS-ChinaTransmissionS

- model

- 80B Sprockets

- Nearest port for product export

- Shanghai, Ningbo, Tianjing, Guangzhou

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, PayPal, Westem Union, Cash

- update time

- Tue, 17 Feb 2026 11:12:44 GMT

Paramtents

Material Stainless Steel

Color Silver

Surface Treatment Blackening/Galvanizing/Phosphating

Accuracy Precision teeth for optimum performance

Quality Superior ANSI Sprocket

Interchangeability Directly interchangeable with other brands

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

About #80B Plain Bore Stainless Steel Sprockets

CTS® #80B plain bore stainless steel sprockets are made from premium stainless steel, these sprockets offer superior corrosion resistance and durability, ensuring reliable operation even in harsh environments. Elevate your industrial operations with our superior #80B plain bore stainless steel sprockets. Count on our expertise to provide tailored solutions for your chain sprockets requirements.

For quotation or other information on stainless steel chain sprockets, please contact us and we will be happy to help you.

Quality Assurance:

ISO9001: 2015 and GB/T24001-2016 / ISO14001: 2015.

Features

- High-precision Sprocket

- Durable Sprocket

- Directly interchangeable with other brands

- OEM Sprocket

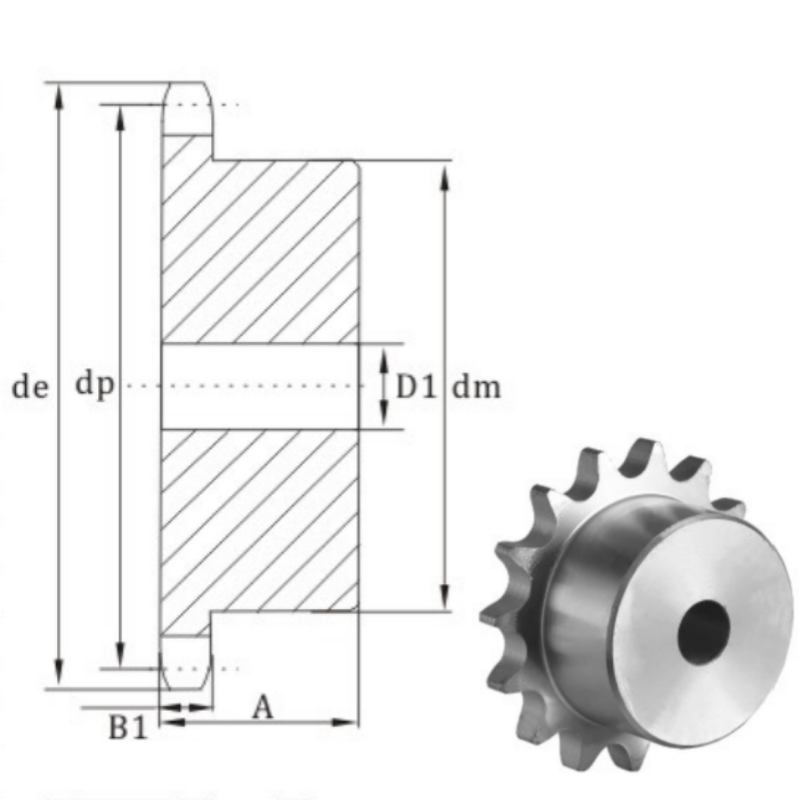

#80B Plain Bore Stainless Steel Sprocket Technical Data

|

Pitch

|

1"

|

|

Roller φ

|

0.625"

|

|

Tooth width B1

|

0.575"

|