Bottle Washer Chain

- group name

- Customized Chains

- Min Order

- 1 piece

- brand name

- CTS-ChinaTransmissionS

- model

- Bottle Washer Chain

- Nearest port for product export

- Shanghai, Ningbo, Tianjing, Guangzhou

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, PayPal, Westem Union, Cash

- update time

- Mon, 09 Feb 2026 16:32:13 GMT

Paramtents

Material Carbon Steel

Color Natural

Surface Treatment Shot Peening/Heat Treatment/Plating/Lubrication

Accuracy High precision industrial chain

Quality Durable industrial chain

Interchangeability Directly interchangeable with other brands

Packging & Delivery

-

Min Order1 piece

Briefing

The Bottle Washer Chain automates cleaning in industrial settings, bottles through various cleaning stages.

Detailed

About Bottle Washer Conveyor Chains

Introducing Bottle Washer Conveyor Chains – essential components crafted from stainless steel, specially designed for use in beverage machinery. These chains play a crucial role in the efficient conveyance of large quantities of bottles at controlled speeds through washing processes within beverage and food production lines.

At CTS® Chain, we stand as a leading manufacturer of Bottle Washer Conveyor Chains in China. Leveraging our extensive technical collaborations with domestic beverage manufacturers and our unwavering commitment to refinement, we proudly present a comprehensive range of Bottle Washer Conveyor Chains tailored to meet the diverse specifications of your conveying requirements.

Quality Assurance:

ISO9001: 2015 and GB/T24001-2016 / ISO14001: 2015.

Features

- Precision Machined Components

- Low Friction

- Directly interchangeable with other brands

- Uniform Heat Treatment

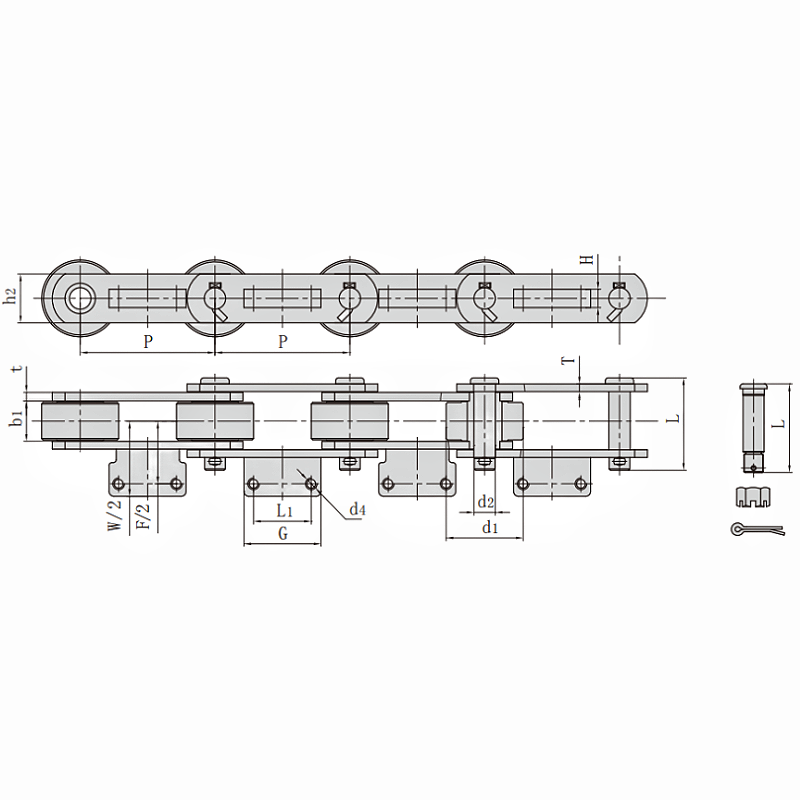

Bottle Washer Conveyor Chain Technical Data

* Each pin with nut

As seasoned experts in transmission chain manufacturing, we boast certifications from reputable standards organizations including ANSI, DIN, BS, and JIS, covering a wide array of products including oilfield chains, lumber conveyor chains, agricultural chains, engineering chains, and more. Renowned for their quality and competitive pricing, our chains are trusted and exported to esteemed destinations worldwide, including the USA, Germany, France, Poland, Indonesia, and beyond. For inquiries or further information, please feel free to reach out to us without hesitation. Your satisfaction is our priority!