Steel Detachable Chains

- group name

- Agricultural Machinery Chain

- Min Order

- 1 piece

- brand name

- CTS-ChinaTransmissionS

- Nearest port for product export

- Shanghai, Ningbo, Tianjing, Guangzhou

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, PayPal, Westem Union, Cash

- update time

- Fri, 30 Jan 2026 04:37:50 GMT

Paramtents

Material Carbon Steel

Color Natural

Surface Treatment Shot Peening/Heat Treatment/Plating/Lubrication

Accuracy High precision pintle chain

Quality Durable pintle chain

Interchangeability Directly interchangeable with other brands

Packging & Delivery

-

Min Order1 piece

Briefing

A steel detachable chain is a high-strength, modular chain designed for heavy-duty applications, offering durability, easy maintenance, and versatility in various industrial and agricultural settings.

Detailed

About Steel Detachable Chains

Steel Detachable Chains are high-strength, durable chains commonly used in heavy-duty applications where reliability and performance are critical. They feature a modular design, allowing individual links to be easily detached or replaced, which makes maintenance and repairs faster and more cost-effective. Typically made from high-quality steel, these chains are engineered to withstand extreme conditions such as high loads, abrasive environments, and exposure to moisture or chemicals. Their versatility makes them ideal for industries such as agriculture (e.g., hay elevators, manure spreaders), material handling (e.g., conveyors), and manufacturing (e.g., assembly lines). The corrosion-resistant properties of these chains, combined with their long lifespan and minimal maintenance needs, make them a preferred choice for many industrial applications.

Quality Assurance:

ISO9001: 2015 and GB/T24001-2016 / ISO14001: 2015.

Features

- Precision Machined Components

- Low Friction

- Directly interchangeable with other brands

- Uniform Heat Treatment

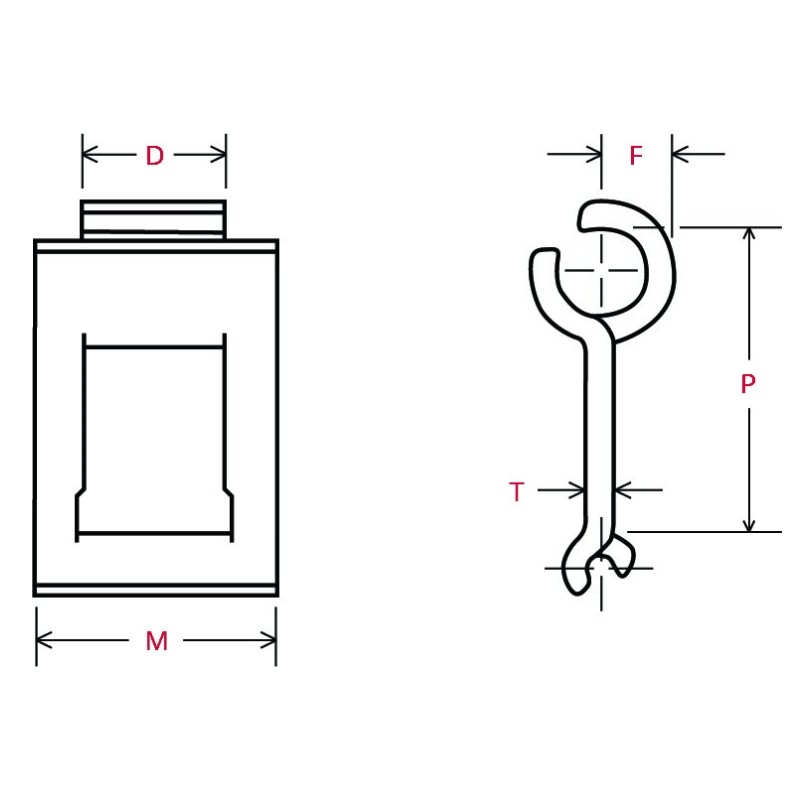

Steel Detachable Chain Dimension