-

Keeping a stock in your industry may seem like a simple task, however, it is not an easy task, it needs attention and care at every step. Having inventory control is essential for every business that has the objective of efficient and organized management in all its stages.

time2021/01/15

PublisherHozie

-

The passage shows the differences between sprockets and gears. CTS-Chinatransmission is devoted to offering high-quality power transmission parts, such as sprockets, chains, gears, racks, couplings and so on.

time2021/03/15

PublisherJulia

-

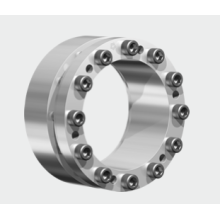

Locking Assemblies is an advanced basic component widely used for mechanical coupling under heavy loads in the world. In the coupling of wheel and shaft, it is produced by tightening high-strength bolts to make the containment surface. A keyless coupling device that realizes load transmission by pressure and friction.

time2021/04/12

PublisherLydia

-

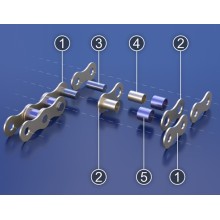

The article introduces the ways to identify different roller chains easily and quickly.

time2021/04/15

-

YQ-ChinaTransmission can ensure every product produced meets strict quality standards. we can offer you sprocket, chain, gear, bush and so on.

time2021/04/20

-

The article will introduce the roller chain couplings and the ways to identify different couplings.

time2021/04/08

PublisherJulia

-

This article introduces the difference between hot-dip zinc plated and electronic zinc plated. Sometimes we will ignore the difference.

time2021/05/10

PublisherJulia

-

Powder metallurgy is a process technology for preparing metal powder or using metal powder (or a mixture of metal powder and non-metal powder) as a raw material, after forming and sintering, to produce metal materials, composite materials and various types of products.

time2021/05/11

-

The method of plating a layer of nickel on metals or certain non-metals by electrolysis or chemical methods is called nickel plating. Nickel plating is divided into electroplating nickel and electroless nickel plating

time2021/05/24

-

The article introduces the material increasment recently in China. YQ.ChinaTransmissions is a professional chains and sprockets supplier.

time2021/05/11

PublisherJulia

-

Bearings should be done to detect cleanliness in order to avoid bearing burns.

time2021/06/08

-

12B chain sprocket is currently widely used in the manufacturing process of machinery, so what is a 12B chain sprocket and what is the specific definition?

time2021/06/25

-

if the transmission chain is inefficient or rusted, how to choose a lubricant to improve its work efficiency

time2021/07/02

-

The sprocket is a round wheel with external teeth.

time2021/07/06

-

Moreover, the advantages of compact sprocket structure make it have larger transmission ratio, and its service life is also relatively high.

time2021/07/08

-

Engineered steel bush chain sometimes referred to as steel knuckle chain (most commonly based on American Standards),which is a wide width bush only chain.Generally interchangeable with cast combination chains and were developed as a superior replacement.

time2021/07/14

-

Welded steel type mill chains have higher tensile strength and manufactured with large carrying surfaces,which are typically found in grain handling, mining, forestry, paper industries and mill applications.

time2021/07/15

-

Welded steel type drag chain is widely used in all walks of life because of its strong durability, wear resistance and corrosion resistance.

time2021/07/16

-

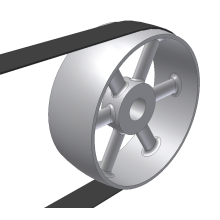

Timing belt pulleys are parts of disc hubs, which are generally relatively large in size. The manufacturing process is generally based on casting and forging.

time2021/07/24

-

Gear is a mechanical element with gears on the rim to continuously mesh and transmit motion and power.

time2021/07/24

-

Gears of different sizes produce a change in torque, creating a mechanical advantage, through their gear ratio, and thus may be considered a simple machine.

time2021/07/28

-

When you planning to purchase new transmission chains,every supplier or saler claim that they will provide excellent price to reduce your cost.You simply need to pay product cost,is it?

time2021/08/05

-

Idler sprocket refers to a sprocket that transmits between two transmission gears that are not in contact with each other and meshes with these two gears at the same time.

time2021/08/10

-

Sprockets are widely used in mechanical transmission in chemical, textile machinery, escalators, wood processing, three-dimensional parking garages, agricultural machinery, food processing, instrumentation, petroleum and other industries.

time2021/08/24

-

The sprocket itself is a bit similar to the shape of a gear, and the effect is very good when used in the case of medium and high speed rotation. So why do you need to design it into a gear row shape? After designing it like this, What can it do?

time2021/08/26

PublisherKimer

-

The commonly used precision couplings are: elastic couplings, diaphragm couplings, slider couplings, plum blossom couplings, rigid couplings.

time2021/08/31

PublisherKimer

-

The working principle of the rack and gear is to transform the rotary motion of the gear into the reciprocating linear motion of the rack, or to transform the reciprocating linear motion of the rack into the rotary motion of the gear.

time2021/09/01

PublisherKimer

-

A V-belt pulley is a mechanical component used to transfer power between a belt and a shaft. It typically has a grooved or V-shaped profile that matches the cross-section of the belt, ensuring efficient power transmission by gripping the belt securely. V-belt pulleys are common in various applications such as industrial machinery, automotive engines, and household appliances.

time2021/09/01

PublisherTaylor

-

Hobbing is a machining process for gear cutting, cutting splines, and cutting sprockets on a hobbing machine, which is a special type of milling machine.

time2021/09/02

PublisherTaylor

-

This 6016 coupling chain is manufactured using high-quality precision heat-treated components to give it the maximum strength, durability and performance that you can expect to get out of a coupling chain

time2021/09/02

-

Bevel gears are gears where the axes of the two shafts intersect and the tooth-bearing faces of the gears themselves are conically shaped. Bevel gears are most often mounted on shafts that are 90 degrees apart, but can be designed to work at other angles as well. The pitch surface of bevel gears is a cone.

time2021/09/06

PublisherTaylor

-

Roller chain is a kind of chain used to transmit mechanical power.

time2021/09/07

PublisherKimer

-

This AK17 Pulley 5/8" bore is directly interchangeable with other manufacturers, is 1.75" in diameter, is used with A style V-Belts.

time2021/09/07

-

The timing pulley is an important part of the engine's air distribution system.It plays a important part in our daily life.

time2021/09/08

PublisherKimer

-

An idler sprocket is a device used to maintain the tension in a chain or chain drive system.

time2021/09/08

PublisherTaylor

-

The bushing is a matching part used outside the mechanical parts to achieve the functions of sealing, wear protection, etc. It refers to the ring sleeve that functions as a gasket.

time2021/09/14

PublisherKimer

-

There are two types of links alternating in the bush roller chain. Inner links and outer links.

time2021/09/14

PublisherTaylor

-

Gear coupling is composed of internal gear ring with the same number of teeth and flange half coupling with external teeth.

time2021/09/15

PublisherKimer

-

Hobbing is a machining process for gear cutting, cutting splines, and cutting sprockets on a hobbing machine, which is a special type of milling machine.

time2021/09/16

PublisherTaylor

-

Precautions for chain use and storage

time2021/09/21

PublisherKimer