-

This article introduces several commonly used packaging of our chain!

time2022/04/25

PublisherKimer

-

Double pitch roller chain is equivalent to standard roller chains just with "double the pitch". For example, #80 roller chain has a 1" pitch and C2080 double pitch roller chain has a 2" pitch but all other dimensions are equal to an ANSI standard #80 roller chain.

time2022/04/27

PublisherKimer

-

The rack and gear will have its own unique movement characteristics in the transmission process: the gear transmission is used to transmit the movement and power between any two axes, its peripheral speed can reach 300m/s, the transmission power can reach 105KW, and the gear diameter can be from Less than 1mm to more than 150m, it is the most widely used mechanical transmission in modern machinery.

time2022/05/03

PublisherKimer

-

The L-shaped jaw coupling is similar to the plum-blossom coupling. It is cast by powder metallurgy and has the characteristics of economy and practicality, easy disassembly, light weight, high torque and wear resistance.

time2022/05/05

PublisherKimer

-

NM coupling, also called male claw coupling. The structure is similar to the elastic plum coupling, using specially designed synthetic rubber, with two similar bodies of cast iron material, rubber type coupling NM series. It is mainly a coupling with two cast iron (FC25 material) bodies plus rubber, rubber The type coupling NM series is cast iron (FC25)

time2022/05/09

PublisherKimer

-

The FCL type elastic coupling conforms to the Japanese national standard JISB1452. The FCL type elastic sleeve pin coupling uses a pin with an elastic sleeve (rubber material) at one end, and is installed in the flange holes of the two halves of the coupling to achieve two The coupling of the half-coupling.

time2022/05/12

PublisherKimer

-

Sprockets often require surface treatment to meet the needs of different customers. There are many surface treatments for sprockets. The following are the most common ones.

time2022/05/16

PublisherKimer

-

Sprocket is a wheel with cog-style sprocket teeth that engages the exact pitch blocks on the link link or cable. Sprockets are widely used in chemical industry, textile machinery, escalators, wood processing, three-dimensional parking garages, agricultural machinery, food processing, instrumentation, mechanical transmission in petroleum and other industries.

time2022/05/18

PublisherKimer

-

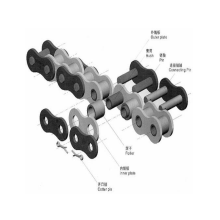

A sprocket is a wheel with cog-style sprocket teeth that engages the exact pitch blocks on the link link or cable. A roller chain is a type of chain used to transmit mechanical power and is a type of chain drive widely used in household, industrial and agricultural machinery, including conveyors, plotters, printing presses, automobiles, motorcycles, and bicycles.

time2022/05/24

PublisherKimer

-

Gears are mechanical parts with teeth on the rim that can continuously mesh to transmit motion and power. Gears rely on the meshing of teeth to transmit torque. A sprocket is a wheel with cog-style sprocket teeth that engages the exact pitch blocks on the link link or cable.

time2022/05/25

PublisherKimer

-

A Chain Drive consists of an endless chain wrapped around two sprockets. The chain consists of a number of links connected by pin joints,while the sprocket are toothed wheels with a special profile for teeth.

time2022/06/01

PublisherKimer

-

The taper bush is a commonly used new type of mechanical transmission connection component, which has the characteristics of high standardization, high precision, compact structure, and convenient installation and disassembly.

time2022/06/02

PublisherKimer

-

This article is main to introduce hydraulic chain breaker.

time2022/06/16

PublisherKimer

-

Roller chains usually refer to precision roller chains for short-pitch transmissions, which are the most widely used and have the most output. The roller chain is divided into single row and multi-row, which is suitable for low power transmission.

time2022/06/21

PublisherKimer

-

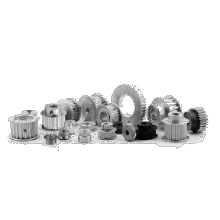

The timing pulley is generally made of steel, aluminum alloy, cast iron, brass and other materials, and its inner hole has the form of round hole, D-shaped hole, tapered hole and so on.

time2022/06/28

PublisherKimer

-

The straight chain chain has the advantage of higher fatigue strength than the standard chain, and can be used like a conveyor chain to directly load the goods on the chain.

time2022/07/05

PublisherKimer

-

The chain coupling uses a common chain and meshes with two parallel sprockets with the same number of teeth at the same time. The main difference between the chain couplings of different structural types is the use of different chains. Roller chain coupling, toothed chain coupling, nylon chain coupling, etc.

time2022/07/18

PublisherKimer

-

The taper sleeve is mainly divided into Taper Lock Bushing, QD Bushing and Split taper bushing. The holes where the taper sleeve and the pulley match are half-sided, and the two light holes on the taper sleeve and the two threaded holes on the pulley are respectively A complete hole is formed, and a threaded hole on the taper sleeve and a smooth hole on the pulley form a complete hole. When assembling, put the two screws in the two threaded holes of the pulley.

time2022/08/02

PublisherKimer

-

In the United States , power transmission chains must meet ANSI B29.1, thus earning the name ANSI chains . In other countries , the chains must meet IS B1801, ISO 606A, or ISQ 1395C.

time2022/08/05

PublisherMelyssa

-

Sprockets and gears are both used to transmit power within machines or to move items by interlocking with them. But what's the difference between them?

time2022/08/05

PublisherMelyssa

-

Weld-on hubs are constructed for use with taper bushes, offering a cost-effective option for stable mounting of ventilators, fan propellers, plate sprockets, and other equipment on a shaft.

time2022/08/11

PublisherKimer

-

-

This AK17 Pulley 5/8" bore is directly interchangeable with other manufacturers, is 1.75" in diameter, is used with A style V-Belts.

time2022/08/12

-

These details should not be ignored when the chain is used. The chain may not be removed during cleaning, or the chain may be removed for thorough cleaning. Thorough cleaning is to remove the chain and soak it in a cleaning agent (gasoline or kerosene) for part of the time, then brush it section by section with a brush. After cleaning, immerse the chain in lubricating oil at 70~80℃, make it oil-filled, and then install and use it.

time2022/09/01

PublisherKimer

-

Chains are classified according to different materials and shapes. This article will introduce some different types of chains.

time2022/09/07

PublisherKimer

-

In fact, the conveyor chain is similar to the transmission chain. The precision conveyor chain is also composed of a series of bearings. They are fixed by the chain plate with restraint function, and the positional relationship between them is very precise. Each bearing consists of a pin and a sleeve on which the rollers of the chain rotate.

time2022/09/14

PublisherKimer

-

The conveyor chain is the same as the transmission chain, and the precision conveyor chain is also composed of a series of bearings, which are fixed by the constraining chain plates, and the positional relationship between them is very precise.

time2022/09/23

PublisherKimer

-

Engineering chains are widely used in manufacturing, metallurgy, palm oil, sugar, environmental protection equipment, construction machinery, bulk material transportation and other industries.

time2022/09/27

PublisherKimer

-

Timing pulleys are generally made of steel, aluminum alloy, cast iron and other materials, and their inner holes are in the form of round holes, D-shaped holes, and tapered holes. The synchronous pulley drive is composed of a closed annular tape with equidistant teeth on the inner peripheral surface and a corresponding pulley.

time2022/10/11

PublisherKimer

-

These are the most common types of sprockets used .

They work only with chains designed by rollers interconnected by pins .

Roller chains provide a gap that the fits the teeth of the sprocket to transfer totary motion .time2022/10/24

PublisherKimer

-

These are the most common types of sprockets used .

They work only with chains designed by rollers interconnected by pins .

Roller chains provide a gap that the fits the teeth of the sprocket to transfer totary motion .time2022/10/24

PublisherKimer

-

The pulley is a tool used to transmit power. According to the volume, function, standard, material and use, it can be divided into dozens of different sub-categories. European standard and American standard are two of these many sub-categories.

time2022/11/03

PublisherKimer

-

Depending on operating conditions such as load, temperature, contamination, corrosive environments, etc., the service life of the chain will vary. Since chains, like any mechanical element, are subject to wear, they should be visually inspected periodically. When inspecting, pay particular attention to signs of wear caused by elongation due to wear, chain tension, lubrication and tilting sprockets (so-called sprockets). Fault tracking effects.

time2022/11/22

PublisherKimer

-

The chain guide has a polyethylene variety with ultra-high molecular weight (usually more than 1.5 million molecular weight). Has excellent impact resistance and self-lubricating properties

time2022/12/06

PublisherKimer

-

Shengzhou Tomorrow Machinery started in 2011 and has a history of 12 years. Shengzhou Tomorrow Machinery can ensure every product produced meets strict quality standards. We are the professional sprockets manufacturer, all products are thoroughly inspected for accuracy throughout the manufacturing process.

time2022/12/13

PublisherKimer

-

These are the most common types of sprockets used .

They work only with chains designed by rollers interconnected by pins .

Roller chains provide a gap that the fits the teeth of the sprocket to transfer totary motion .time2022/10/24

PublisherEmma

-

A roller chain sprocket is a type of sprocket that is specifically designed for use with a roller chain.

time2023/03/31

-

Hobbing the inner gear is a common gear manufacturing process. The general steps for hobbing the inner gear include machine setup, workpiece preparation, hobbing cutter selection, tool setup, determination of cutting parameters, cutting operation, cooling and lubrication, quality control, and finishing steps. It requires specialized equipment and expertise, and the specific steps and techniques may vary depending on the machine and gear design requirements.

time2023/09/05

PublisherKimer

-

Please note that the process for assembling large pitch chains may vary based on the specific chain type and manufacturer's recommendations. Always refer to the product manual or manufacturer's instructions for the most accurate and detailed guidance.

time2023/09/05

PublisherEmma

-

CNC internal gear milling is a machining process used to produce internal gears using a CNC (Computer Numerical Control) milling machine. It involves removing material from a workpiece to create the internal gear profile.

time2023/09/05

PublisherEmma