-

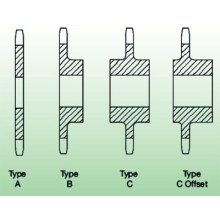

Sprockets are available with 1, 2 or 3 rows of teeth to suit the chain they are working with - simplex, duplex or triplex sprockets.

time2023/09/08

PublisherKimer

-

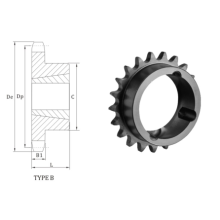

Taper bore sprockets are a type of sprocket used in various mechanical systems, especially in power transmission applications like conveyor systems, industrial machinery, and roller chains. These sprockets are designed with a tapered bore, which means the central hole (bore) through which they are mounted onto a shaft is tapered or conical in shape.

time2023/09/11

PublisherRobert

-

Taper bore sprockets are a type of sprocket used in various mechanical systems, especially in power transmission applications like conveyor systems, industrial machinery, and roller chains. These sprockets are designed with a tapered bore, which means the central hole (bore) through which they are mounted onto a shaft is tapered or conical in shape.

time2023/09/11

PublisherRobert

-

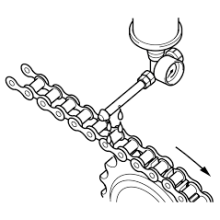

Dirt and contaminants can cause premature wear and affect the performance of the roller chain. Regularly remove any accumulated dirt or debris from the roller chain using a brush or compressed air.

time2023/09/11

PublisherRobert

-

"Tooth harding" is a heat treatment process commonly used to enhance the hardness and wear resistance of gears and toothed components. In this process, gears or toothed components are first heated to a specific temperature, typically above the critical point, to alter their crystalline structure. Subsequently, rapid cooling, often using oil, water, or gas, is employed to cool the heat-treated region, thereby harding it.

time2023/09/11

PublisherRobert

-

Industry sprockets are widely used in various industrial applications for power transmission and motion control. They are essential components in machinery, equipment, vehicles, and conveyor systems. Sprockets engage with chains or belts to transmit rotary motion and power between rotating shafts. They are commonly found in industries such as manufacturing, automotive, transportation, agriculture, and logistics.

time2023/09/12

PublisherKimer

-

Roller chains are made up of cylindrical rollers connected by links and are commonly used in power transmission systems. Engineering chains, on the other hand, consist of interconnected, flat and elongated plates or links, and are often used in conveyor systems for material handling. The two types of chains have different designs, construction, applications, and load capacities.

time2023/09/12

PublisherKimer

-

Internal gear shaping with a 50° helix angle refers to the process of manufacturing internal gears with teeth that have a helix angle of 50 degrees.

time2023/09/14

PublisherEmma

-

Replacing the chain, sprockets, and bushes typically involves several steps.

time2023/09/14

PublisherEmma

-

The manufacturing process of flexible couplings involves several key steps. The process typically begins with the selection of suitable materials based on the intended application. Different components, such as hubs, flanges, and flexible elements, are then fabricated individually using techniques like casting, machining, forging, or molding. These components are subsequently assembled together, ensuring precise alignment and fit.

time2023/09/18

PublisherKimer

-

Sprocket is a mechanical element used to cooperate with a chain, usually to transmit power and achieve rotational motion. When used in conjunction with a chain, the sprocket transmits the power of the chain to the rotating shaft to realize the movement or rotation of the object.

time2023/09/18

PublisherRobert

-

Chain Coupling: Interlocking chains transmit torque and provide flexibility for high-torque applications.

Jaw Coupling: Two hubs with elastomeric curved jaws provide simplicity, compact design, and vibration damping.

FCL Coupling: Also known as a floating shaft coupling, it uses a membrane design for angular misalignment compensation.

NM Coupling: Lovejoy couplings use elastomeric spider inserts with curved jaws for flexibility and vibration damping.time2023/09/18

PublisherKimer

-

Sprockets have different numbers of teeth to meet different application requirements. Different number of teeth affects speed, torque transmission, force distribution and smoothness of motion.

time2022/10/11

PublisherRobert

-

The process of working with timing pulleys typically involves several steps.

time2023/09/22

PublisherEmma

-

Designing and producing a gear involves several steps. Here is a general guide to help you understand the process:

time2023/09/22

PublisherEmma

-

A spur rack is a type of linear gear with straight teeth that mesh with a pinion gear to convert rotary motion into linear motion.

time2023/09/25

PublisherKimer

-

The MN coupling, also known as the Muffelex Coupling, is a type of flexible coupling used to connect two rotating shafts in machinery. It is designed to accommodate misalignment, reduce vibrations, and transmit torque between the connected shafts. The MN coupling consists of two hubs and an elastomeric element.

time2023/09/25

PublisherEmma

-

The MN coupling, also known as the Muffelex Coupling, is a type of flexible coupling used to connect two rotating shafts in machinery. It is designed to accommodate misalignment, reduce vibrations, and transmit torque between the connected shafts. The MN coupling consists of two hubs and an elastomeric element.

time2023/09/25

PublisherEmma

-

These three types of racks offer different characteristics and application capabilities, allowing them to be applied in various industries and machinery that require linear motion, precision, and power transmission

time2023/09/25

PublisherKimer

-

Hobbing is a common manufacturing process used to produce sprockets with accurate tooth profiles

time2023/09/27

PublisherEmma

FormHow to hobbing sprocket

-

Tapered bore v-pulleys, incorporating an appropriate tapered bush, offer a convenient, quick and easy installation

time2023/10/08

PublisherKimer

-

Shanghai PTC will open from 23th, October to 27th October, welcome to visit us.

time2023/10/09

PublisherKimer

-

Milling spiral bevel gears is a complex process that requires precision and expertise. Here are some key points to consider:

time2023/10/11

PublisherEmma

FormMilling of spiral bevel gear

-

Cutting bevel gears on a milling machine involves a different approach compared to spiral bevel gears.

time2023/10/11

PublisherEmma

FormBevel gear cutting on milling machine

-

Cutting bevel gears on a milling machine involves a different approach compared to spiral bevel gears.

time2023/10/11

PublisherEmma

FormBevel gear cutting on milling machine

-

A gear rack is a type of gear on which gear teeth are cut on one face of a bar. The bar can be square, round or rectangular in cross section and the teeth can be either parallel to the base or set at an angle. They are a simple and common type of element in mechanical drive systems and are always paired with a pinion.

time2023/10/16

PublisherKimer

-

An idler sprocket is an essential component in many mechanical systems. Its primary function is to guide and maintain the proper tension of a chain or belt that is transmitting power.

time2023/10/16

PublisherKimer

-

Cutting bevel gears on a milling machine involves a different approach compared to spiral bevel gears.

time2023/10/11

PublisherEmma

FormRemove the Sprocket‘s Bur

-

Removing burrs from a sprocket is important for several reasons.

time2023/10/11

PublisherEmma

Formwhy the sprocket need Remove the Bur

-

Gear laser quenching, also known as laser hardening or laser surface hardening, is a heat treatment process used to enhance the hardness and wear resistance of gear teeth. It involves using a high-energy laser beam to rapidly heat the surface of the gear teeth and then quickly cooling it off, resulting in a hardened layer on the gear surface.

time2023/10/11

PublisherEmma

Formwhy the sprocket need Remove the Bur

-

The manufacture process of v-belt pulley: Material Prepation - Cast Iron - CNC Maching - Grooving - Surface Treatment -Cleaning & Packing

time2023/11/02

PublisherKimer

-

The manufacture process of locking assembly is : Material Preparation - CNC Maching - Bore Drilling - Benching Process - Assemble - Cleaning & Packing

time2023/11/02

PublisherKimer

-

QD bushings, also known as quick-disconnect bushings, are used throughout the industrial power transmission and agricultural industries for various sprocket, sheave, pulley, and synchronized drive needs.

time2023/11/07

PublisherKimer

-

The split tapered bushing alleviates the need to have a component bored to size, ideally lowering on hand requirements and allowing for changes in shaft size if necessary. The barrel of the split tapered bushing is split in two places and is keyed to the shaft.

time2023/11/07

PublisherKimer

-

Taper Bore Weld-on-Hubs are made out of steel, drilled, tapped and taper bored to receive standard Taper Bushes.

time2023/11/13

PublisherKimer

-

Agricultural Roller Chains are manufactured of hardened steel parts to close tolerances. They provide high quality, increased strength and longer life within their service range.

time2023/11/15

PublisherKimer

-

Brand new upgrade: YQ Rebrands to CTS®

time2024/04/30

-

-

Join CTS-ChinaTransmissionS at the 2024 Shanghai PTC ASIA for high-quality products and the latest transmission solutions.

time2024/10/09

-

CTS-ChinaTransmissions participate in Shanghai PTC ASIA 2015.

time2015/10/27